Durable Cap for Galvanized Pipe - Protect Your System

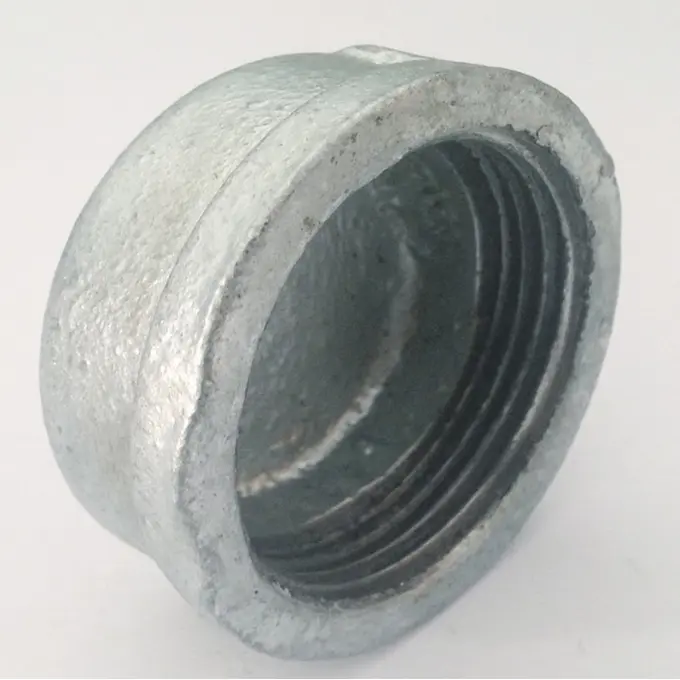

Elevating Industrial Connectivity: The Essential Role of Galvanized Malleable Iron Round Caps

In the intricate world of industrial fluid and gas conveyance systems, the integrity and longevity of every component are paramount. Among these critical elements, the cap for galvanized pipe stands out as a fundamental fitting designed to seal off the end of a pipeline, preventing leakage, protecting internal systems from external contaminants, and facilitating future expansions or maintenance. This specialized fitting is crucial in environments where corrosion resistance and robust mechanical strength are non-negotiable. Engineered from high-grade malleable iron and fortified with a zinc coating, these caps ensure superior performance and extended service life in demanding applications ranging from complex industrial setups to municipal water infrastructure.

The demand for reliable and durable pipe fittings has never been higher, driven by global infrastructure development and the need for sustainable, long-lasting solutions. Understanding the nuanced technical specifications, manufacturing processes, and diverse application scenarios of products like the cap for galvanized pipe is essential for B2B decision-makers and technical procurement specialists. This comprehensive guide delves into the core aspects of Galvanized Malleable Iron Round Caps, highlighting their strategic importance in maintaining operational efficiency and safety across various sectors.

The Manufacturing Excellence: Crafting a Robust Cap for Galvanized Pipe

The production of a high-quality cap galvanized pipe involves a meticulously controlled multi-stage process, beginning with the selection of premium raw materials and culminating in rigorous quality assurance. The foundational material, malleable iron, is chosen for its excellent machinability, ductility, and ability to withstand significant shock and vibration.

Material Selection and Foundry Operations

The journey begins with carefully selected pig iron and steel scrap, melted in induction furnaces to precise metallurgical compositions. This molten metal is then poured into prepared molds, a process known as casting. Precision casting techniques ensure that each cap for galvanized pipe achieves uniform wall thickness and intricate thread formation, critical for secure connections. After solidification, the rough castings undergo annealing – a heat treatment process that transforms brittle white iron into ductile malleable iron, significantly enhancing its mechanical properties and making it suitable for subsequent machining and galvanization.

Precision Machining and Threading

Post-annealing, the malleable iron caps proceed to the machining stage. Advanced CNC (Computer Numerical Control) machining centers are employed to precisely cut and finish the threads according to international standards such as ANSI B1.20.1 for NPT threads or ISO 7-1 for BSP threads. This precision is vital to ensure a leak-proof connection when the cap for galvanized water pipe is installed. Any deviation in thread dimensions can compromise system integrity, leading to costly leaks and operational disruptions. Quality control at this stage involves sophisticated gauging to verify thread accuracy and concentricity.

Hot-Dip Galvanization Process

The defining characteristic of these caps is their galvanization. After cleaning and fluxing, the caps are immersed in a bath of molten zinc at approximately 450°C (840°F). This hot-dip galvanization process creates a metallurgically bonded zinc coating that provides superior corrosion resistance. The zinc layer acts as a sacrificial anode, protecting the underlying iron even if the coating is scratched. This robust layer significantly extends the product's lifespan, often exceeding 50 years in typical atmospheric conditions, far surpassing ungalvanized alternatives and making it an ideal cap galvanized pipe for harsh environments.

Stringent Quality Control and Testing

Before packaging, every cap for galvanized pipe undergoes a series of rigorous inspections. This includes visual checks for surface defects, dimensional verification using precision calipers and gauges, and pressure testing to ensure integrity under specified operating pressures. Adherence to international standards such as ISO 9001 for quality management systems and ANSI/AWWA standards for pipe fittings ensures that each product meets the highest benchmarks for reliability and performance. This commitment to quality minimizes field failures and provides assurance to clients.

Technical Specifications and Performance Metrics

Understanding the precise technical parameters of a cap galvanized pipe is critical for proper system design and material selection. These specifications directly impact the fitting's compatibility, performance, and longevity within a given application.

| Parameter | Description | Typical Value/Standard |

|---|---|---|

| Material | Malleable Iron (ASTM A197/EN 1562) | Whiteheart or Blackheart Malleable Iron |

| Coating | Hot-Dip Galvanized Zinc Coating | Min. 70 μm (ASTM A153/EN ISO 1461) |

| Thread Standard | Taper Pipe Threads | ANSI B1.20.1 (NPT) or ISO 7-1 (BSP/BSPT) |

| Pressure Rating | Maximum Working Pressure | Class 150 (2 MPa / 300 psi) or Class 300 (4.1 MPa / 600 psi) |

| Temperature Range | Operating Temperature | -20°C to +120°C (-4°F to +248°F) |

| Corrosion Resistance | Salt Spray Test Compliance | >1000 hours (ASTM B117) |

| Available Sizes | Nominal Pipe Size (NPS) | 1/2" to 4" (DN15 to DN100) common |

These parameters collectively define the performance envelope of a cap galvanized water pipe. The high-pressure ratings confirm their suitability for critical fluid transfer systems, while the broad temperature range ensures stable operation across diverse climatic conditions. The robust corrosion resistance, primarily due to the sacrificial zinc coating, is particularly vital for outdoor installations or applications involving aggressive media, minimizing maintenance costs and ensuring operational continuity.

Diverse Applications and Strategic Advantages

The versatility and inherent advantages of Galvanized Malleable Iron Round Caps make them indispensable across a wide spectrum of industrial and commercial applications. Their primary function, to safely terminate pipeline sections, is executed with a level of durability that few other materials can match.

Applicable Industries and Use Cases

- Petrochemical Industry: Used in refineries and chemical plants for temporary or permanent capping of utility lines, water lines, or low-pressure gas lines, where robust corrosion resistance against atmospheric elements is crucial.

- Metallurgy and Mining: Applied in process water systems and dust suppression lines, where mechanical strength and resistance to abrasive conditions are required. The durability of a cap galvanized pipe ensures longevity in harsh, often outdoor, environments.

- Water Supply and Drainage Systems: Found extensively in municipal and industrial water networks, including potable water lines and wastewater treatment facilities, offering a reliable, long-term solution for terminating distribution lines or access points.

- Fire Protection Systems: Essential for capping sprinkler system risers during construction or for future expansion points, maintaining system integrity and pressure.

- HVAC and Refrigeration: Used in large-scale commercial and industrial HVAC systems for capping water or coolant lines, ensuring leak-free operation.

- Agriculture and Irrigation: Employed in large-scale irrigation systems for capping water mains or branch lines, providing resilience against environmental exposure.

Key Technical Advantages

- Exceptional Corrosion Resistance: The hot-dip galvanized coating provides a robust barrier against rust and oxidation, particularly vital in humid, outdoor, or chemically aggressive environments. This significantly extends the service life compared to ungalvanized alternatives.

- High Mechanical Strength and Ductility: Malleable iron offers a superior combination of strength and ductility, making the cap for galvanized pipe resistant to impact, shock, and thermal expansion/contraction, reducing the risk of brittle fracture.

- Leak-Proof Sealing: Precision-machined threads (NPT/BSP) ensure a tight, secure fit with corresponding pipe threads, preventing leaks and maintaining system pressure, which translates to reduced water/energy loss and improved operational efficiency.

- Cost-Effectiveness and Longevity: While the initial investment might be slightly higher than some alternatives, the extended lifespan and minimal maintenance requirements of a cap galvanized water pipe result in a lower total cost of ownership over its operational life.

- Versatility: Compatible with various galvanized steel pipe types and suitable for both interior and exterior applications, adapting to diverse project requirements.

The strategic adoption of Galvanized Malleable Iron Round Caps not only addresses immediate capping needs but also contributes to the long-term sustainability and efficiency of fluid conveyance systems. Their inherent properties support energy conservation by preventing leaks and ensuring system integrity, thereby reducing the need for constant repressurization.

Industry Trends, Vendor Comparison, and Custom Solutions

The market for pipe fittings is constantly evolving, with increasing emphasis on sustainability, enhanced performance, and technological integration. For a cap for galvanized pipe, current trends lean towards improved coating technologies, smarter manufacturing processes, and comprehensive supply chain solutions.

Choosing the Right Supplier: Key Considerations

When selecting a supplier for your cap galvanized pipe needs, a holistic evaluation is crucial. Beyond standard product specifications, consider factors that speak to a vendor's reliability and commitment to partnership:

- Certifications and Compliance: Verify adherence to international standards like ISO 9001, ANSI, and local regulations. Certifications from bodies like UL or FM for specific applications (e.g., fire protection) are also indicators of superior quality.

- Manufacturing Capabilities: A supplier with advanced casting, CNC machining, and state-of-the-art galvanization facilities ensures consistent product quality and reliable production volumes.

- Technical Support and Expertise: Access to engineering support, detailed product data sheets, and installation guidance can be invaluable for complex projects.

- Customization Options: The ability to provide bespoke solutions (e.g., specific thread types, non-standard sizes, or unique pressure ratings) is a significant advantage for specialized industrial applications.

- Supply Chain Efficiency: Timely delivery and efficient logistics are critical in B2B procurement, minimizing project delays and costs.

A key differentiating factor for leading manufacturers is their capacity for innovation and client-specific customization. While standard sizes of cap for galvanized pipe cover most needs, certain industrial setups may require unique dimensions or specialized coatings. Partnering with a manufacturer capable of delivering custom-engineered solutions ensures perfect fit and optimal performance for even the most demanding projects, from prototype development to large-scale production runs.

Commitment to Quality, Reliability, and Service

At the heart of every successful B2B partnership is unwavering trust, built on a foundation of quality products and dependable service. For critical components like a cap galvanized water pipe, this commitment extends from the manufacturing floor to post-sales support.

Certifications and Authoritative Compliance

Reputable manufacturers ensure their Galvanized Malleable Iron Round Caps meet or exceed stringent international standards. This includes adherence to ISO 9001:2015 for quality management systems, ensuring consistent product quality through every stage of production. Products often comply with specific material standards like ASTM A197 for malleable iron and coating standards like ASTM A153/EN ISO 1461 for hot-dip galvanization. Compliance with these standards is independently verified through third-party audits and certifications, providing an objective assurance of product integrity and performance.

Comprehensive Testing and Quality Assurance

Beyond standard visual and dimensional checks, advanced testing methodologies are employed. This includes hydrostatic pressure testing to verify burst strength and leak integrity under operational conditions, mechanical property tests (tensile strength, elongation) on material samples, and non-destructive testing (NDT) methods like eddy current or magnetic particle inspection to detect internal flaws. Salt spray tests (e.g., ASTM B117) are regularly conducted to evaluate and confirm the long-term corrosion resistance of the galvanized coating, providing concrete data on the durability of the cap for galvanized pipe.

Delivery, Warranty, and Customer Support

Understanding the critical timelines of industrial projects, efficient delivery is paramount. Manufacturers typically offer clear delivery schedules and leverage robust logistics networks to ensure timely arrival of products. A standard product warranty (e.g., 5-10 years) covering manufacturing defects provides an additional layer of trustworthiness. Furthermore, dedicated customer support teams and technical experts are available to assist with product selection, installation guidance, and troubleshooting, ensuring seamless integration of the cap galvanized pipe into client systems. This end-to-end support model reflects a genuine partnership approach.

Frequently Asked Questions (FAQ)

Q1: What is the primary advantage of a galvanized cap over an ungalvanized one?

The primary advantage of a cap for galvanized pipe is its superior corrosion resistance. The zinc coating, applied through hot-dip galvanization, provides a robust barrier against rust and extends the lifespan of the fitting, especially in outdoor, humid, or aggressive environments. This significantly reduces maintenance and replacement costs over time.

Q2: Are these caps suitable for potable water systems?

Yes, Galvanized Malleable Iron Round Caps are widely used in potable water systems. The galvanization process typically uses pure zinc, which is safe for drinking water. However, it's always advisable to check local regulations and specific product certifications (e.g., NSF/ANSI 61 for drinking water components) to ensure full compliance for a cap galvanized water pipe in such critical applications.

Q3: How do I ensure a leak-proof connection when installing a cap?

To ensure a leak-proof connection for a cap galvanized pipe, proper thread preparation is key. Always use appropriate thread sealant or PTFE tape on the male threads of the pipe. Ensure the cap is tightened sufficiently, but avoid over-tightening, which can strip threads or stress the fitting. Professional installation according to industry best practices is recommended.

Q4: What is the expected service life of a Galvanized Malleable Iron Round Cap?

Under typical operating conditions and environments, a well-manufactured cap galvanized pipe can have a service life exceeding 50 years. This longevity is attributed to the inherent durability of malleable iron and the excellent sacrificial protection offered by the hot-dip galvanized zinc coating, which significantly slows down corrosion.

References

- ASTM International. (n.d.). ASTM A153 / A153M - 17: Standard Specification for Zinc Coating (Hot-Dip) on Iron and Steel Hardware.

- ISO. (n.d.). ISO 7-1: Pipe threads where pressure-tight joints are made on the threads — Part 1: Dimensions, tolerances and designation.

- American National Standards Institute (ANSI). (n.d.). ANSI/ASME B1.20.1: Pipe Threads, General Purpose (Inch).

- Galvanizers Association. (n.d.). The longevity of hot dip galvanized steel.