H Steel Bar & 1-Inch Steel Bar: Quality & Best H Bar Price

The Backbone of Modern Infrastructure: Understanding H Steel Bar

In the realm of advanced structural engineering and robust industrial construction, the h steel bar stands as an indispensable component. Characterized by its distinctive 'H' shaped cross-section, this profile offers exceptional strength-to-weight ratio and superior load-bearing capabilities, making it a cornerstone for a myriad of applications from towering skyscrapers to critical infrastructure. Its design ensures optimal distribution of stress, minimizing material usage while maximizing structural integrity and safety. This comprehensive guide delves into the intricate details of H steel bars, exploring their manufacturing excellence, technical prowess, diverse applications, and the critical factors that define their market value and performance. We aim to provide B2B decision-makers and technical professionals with a deep understanding of why H steel bars are the preferred choice for demanding projects globally, emphasizing their role in sustainable and efficient construction practices.

The increasing complexity of modern architectural and industrial designs necessitates materials that not only meet stringent performance requirements but also contribute to long-term operational efficiency and environmental sustainability. H steel bar, with its inherent versatility and engineered precision, perfectly aligns with these evolving demands. Its widespread adoption is a testament to its reliability and the continuous innovation in steel manufacturing processes. We will explore the latest industry trends, shedding light on how these advancements are shaping the future of construction and heavy industry, particularly focusing on the role of high-quality steel products in achieving ambitious project goals.

Industry Trends and Market Dynamics for H Steel Bar

The global market for h steel bar is experiencing dynamic shifts, driven by several key macro and micro-economic factors. A primary driver is the accelerating pace of urbanization and infrastructure development worldwide, particularly in emerging economies. Governments are investing heavily in new transportation networks, commercial buildings, and industrial facilities, all of which rely extensively on structural steel. Furthermore, the push towards green building initiatives and sustainable construction practices is increasing demand for steel, given its recyclability and long service life. Innovations in steel production, such as the adoption of electric arc furnaces (EAF) and advanced rolling technologies, are also contributing to higher quality and more cost-effective products, influencing the overall h bar steel price.

Another significant trend is the increasing customization required by specialized projects. Clients are not merely seeking standard dimensions but often require specific lengths, unique steel grades, or integrated fabrication services like pre-drilling or welding. This shift is compelling manufacturers to offer more flexible production capabilities and value-added services. The market is also seeing greater emphasis on supply chain reliability and transparency, especially after global disruptions. Manufacturers who can guarantee consistent quality, timely delivery, and robust customer support are gaining a competitive edge. The demand for various sizes, including the versatile 1 inch steel bar, also reflects the diverse needs of the market, from lightweight structures to heavy-duty frameworks.

The Meticulous Manufacturing Process of H Steel Bar

The production of a high-quality h steel bar is a sophisticated industrial process, predominantly relying on hot rolling technology to achieve its characteristic shape and superior mechanical properties. This intricate process involves several stages, each meticulously controlled to ensure adherence to stringent international standards and precise specifications.

1. Raw Material Selection & Preparation:

The journey begins with the careful selection of raw materials, primarily steel billets or blooms. The chemical composition of these initial steel forms is critical, as it dictates the final properties of the h steel bar. Common steel grades utilized include ASTM A36, A992, and European standards like EN S275, S355, and S460. These grades are chosen for their specific combinations of tensile strength, yield strength, weldability, and corrosion resistance, suitable for various structural applications. Rigorous pre-inspection ensures the absence of defects and verifies the material's metallurgical integrity.

2. Heating and Descaling:

Selected steel billets are first heated uniformly in a reheating furnace to temperatures typically ranging from 1100°C to 1250°C (2012°F to 2282°F). This elevated temperature makes the steel ductile and malleable, ideal for the subsequent rolling process. Before entering the rolling mill, the heated billets undergo a descaling process, often using high-pressure water jets, to remove surface oxides (mill scale). This step is crucial to prevent surface imperfections on the finished h steel bar and ensures a smooth, clean surface.

3. Hot Rolling Process:

The heated, descaled billet then enters a series of rolling stands, where it is progressively shaped into the desired 'H' profile. This process, known as hot rolling, involves passing the steel through sets of grooved rolls that gradually reduce its cross-sectional area and elongate it, while simultaneously forming the web and flange sections. The rolling mill typically consists of:

- Roughing Stands: Initial reduction in cross-section and elongation of the billet.

- Intermediate Stands: Further shaping of the profile, bringing it closer to the final H-shape.

- Finishing Stands: Precision rolling to achieve the exact dimensions, straightness, and surface finish required for the h steel bar. Advanced rolling technologies, such as universal rolling mills, are employed to ensure the uniform thickness of the web and flanges.

4. Cooling and Straightening:

After hot rolling, the newly formed h steel bar is cooled in a controlled manner, typically on a cooling bed. Controlled cooling is vital to achieve the desired microstructure and mechanical properties, minimizing internal stresses and distortion. Once cooled, the bars are often subject to a straightening process using roller straighteners to ensure they meet precise dimensional tolerances and straightness requirements. This is particularly important for long structural members to facilitate ease of assembly on construction sites.

5. Cutting and Finishing:

The continuous h steel bar is then cut to specified lengths using hot saws. Depending on customer requirements, further finishing operations may include shot blasting for surface preparation, painting, galvanizing for enhanced corrosion resistance, or other protective coatings. Some manufacturers also offer cold forming processes for specific, smaller profiles or for applications requiring tighter tolerances than hot rolling can provide, though hot rolling is dominant for typical structural H-bars.

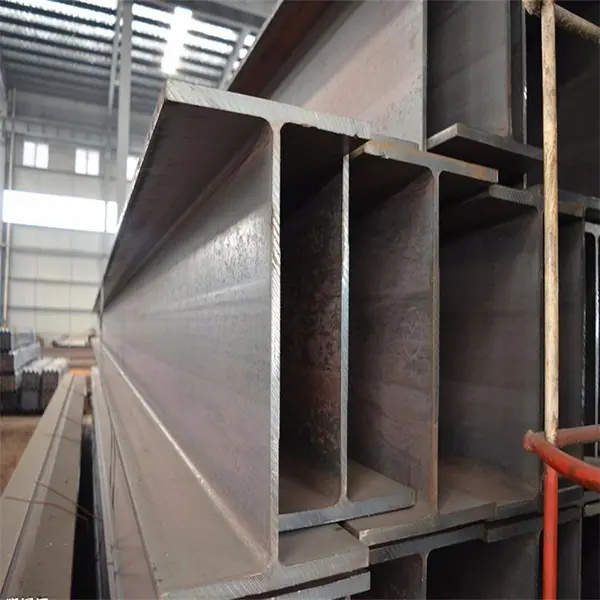

Figure 1: Illustration of diverse steel profiles commonly produced in steel mills, including h steel bar.

6. Quality Inspection and Testing:

Throughout the entire manufacturing process, rigorous quality control and inspection protocols are implemented to ensure that every h steel bar meets or exceeds industry standards. Key inspection standards include:

- ISO 9001: Quality Management System certification, ensuring consistent product quality and customer satisfaction.

- ASTM International (American Society for Testing and Materials): Standards like ASTM A6/A6M for general requirements for rolled structural steel bars, plates, shapes, and sheet piling.

- ANSI (American National Standards Institute): Often referenced for dimensional and testing methods.

- EN (European Norms): Standards such as EN 10025 for hot rolled structural steel sections.

- CE Marking: For products sold within the European Economic Area, indicating conformity with health, safety, and environmental protection standards.

Testing includes:

- Chemical Composition Analysis: Ensuring the correct alloy content.

- Mechanical Testing: Tensile strength, yield strength, elongation, and impact toughness (e.g., Charpy V-notch test) to verify load-bearing capabilities and ductility.

- Dimensional Inspection: Precise measurements of web thickness, flange width, and overall depth to ensure conformity with specified tolerances. This is crucial for seamless integration into construction projects.

- Non-Destructive Testing (NDT): Techniques such as ultrasonic testing may be employed to detect internal flaws or imperfections within the h steel bar.

- Surface Finish Inspection: Visual and instrumental checks for surface defects, straightness, and twist.

The adherence to these rigorous quality control measures and international standards guarantees that each h steel bar delivered offers maximum safety, reliability, and an extended service life in demanding operational environments.

Technical Advantages and Performance Superiority of H Steel Bar

The unique 'H' profile of the h steel bar is not merely an aesthetic choice; it is an engineering marvel designed to deliver superior performance characteristics that are unmatched by many other structural forms. Its strategic design maximizes efficiency and strength, leading to significant benefits across various industrial and construction applications.

- Exceptional Strength-to-Weight Ratio: One of the most significant advantages of h steel bar is its optimized cross-section, which provides high moment of inertia and section modulus relative to its weight. This translates to substantial load-bearing capacity with less material, reducing overall structural weight. Lighter structures lead to reduced foundation requirements, lower transportation costs, and faster erection times, directly impacting project budgets and timelines.

- Superior Load-Bearing Capacity: The wide flanges and deep web create a robust section that efficiently resists bending, compression, and shear forces. This makes h steel bar ideal for critical load-bearing applications such as columns, beams, and girders in large-span structures and high-rise buildings. Its ability to handle heavy loads under various static and dynamic conditions ensures structural stability and safety.

- Excellent Seismic Performance: Steel structures, especially those incorporating h steel bar, exhibit inherent ductility, allowing them to deform significantly without fracturing under seismic events. This energy-dissipating capacity makes steel a preferred material in earthquake-prone regions, enhancing the resilience and safety of buildings and bridges. The flexibility and elasticity of steel contribute to the overall structural integrity during lateral forces.

- Ease of Fabrication and Erection: The standardized dimensions and consistent quality of h steel bar facilitate prefabrication and on-site assembly. Steel structures can be rapidly erected, significantly accelerating construction schedules. Welding, bolting, and other joining methods are straightforward, contributing to lower labor costs and improved project efficiency. This ease of working with the material also allows for intricate and precise structural designs.

- High Versatility and Design Flexibility: H steel bar is available in a wide range of sizes, from smaller sections like a 1 inch steel bar (referring to a small H-beam's dimension) suitable for light frames, to massive sections for heavy industrial applications. This versatility allows architects and engineers unparalleled design freedom, enabling the creation of innovative and aesthetically pleasing structures while maintaining structural integrity. Its adaptability makes it suitable for both new construction and renovation projects.

- Durability and Longevity: When properly designed and protected (e.g., through galvanization or fireproofing), h steel bar structures offer exceptional durability and a long service life, often exceeding 50-100 years. Their resistance to pests, rot, and other environmental degradation contributes to lower maintenance costs over the lifespan of a structure, providing long-term value.

- Sustainability and Recyclability: Steel is one of the most recycled materials globally, with over 90% of structural steel being recycled at the end of a building's life. This makes h steel bar an environmentally friendly choice, reducing the demand for virgin resources and minimizing landfill waste. Its inherent recyclability aligns perfectly with circular economy principles and green building certifications.

- Corrosion Resistance (with treatment): While steel itself can corrode, h steel bar can be treated with various protective coatings, such as hot-dip galvanizing, zinc-rich primers, or specialized paint systems, to provide excellent corrosion resistance, especially in harsh or marine environments. This extends the product's service life significantly, reducing the need for premature replacement and associated costs.

- Energy Efficiency: The use of steel structures can indirectly contribute to energy efficiency. Their lighter weight can reduce the energy consumed in transportation. Furthermore, the inherent thermal properties of steel can be integrated into designs that optimize insulation and HVAC systems, leading to lower operational energy consumption in buildings. The ability to create larger spans with less material can also open up spaces that allow for more natural light and ventilation.

These combined advantages underscore why h steel bar remains a paramount choice for engineers, architects, and contractors seeking optimal performance, cost-efficiency, and sustainability in their construction and industrial projects.

Technical Parameters and Specifications of H Steel Bar

Understanding the technical parameters of h steel bar is crucial for precise engineering design and ensuring structural integrity. These parameters define the material's mechanical properties, chemical composition, and dimensional characteristics, all of which are critical for selecting the right bar for specific applications. Here, we present common specifications and properties relevant to various industry standards.

Mechanical Properties:

- Tensile Strength (Rm): The maximum stress the material can withstand while being stretched or pulled before breaking. Measured in MPa (megapascals) or psi (pounds per square inch). For common structural grades like ASTM A36, it's typically 400-550 MPa (58-80 ksi). For higher strength steels like A992, it can reach 450-620 MPa (65-90 ksi).

- Yield Strength (ReH): The stress at which the material begins to deform plastically (permanently). This is a critical design parameter. For A36, it's approximately 250 MPa (36 ksi); for A992, it's 345 MPa (50 ksi) or 448 MPa (65 ksi).

- Elongation: A measure of the material's ductility, indicating how much it can stretch before fracturing. Expressed as a percentage of the original length. Higher elongation signifies better ductility and toughness, crucial for seismic performance. Typically ranges from 18% to 22% for structural steels.

- Impact Toughness (Charpy V-notch): Measures the material's ability to absorb energy and resist fracture at specific temperatures, crucial for applications in cold climates or dynamic loading. Values are given in Joules (J) at a specific temperature (e.g., 20J at 0°C).

- Modulus of Elasticity (E): Represents the material's stiffness or resistance to elastic deformation under stress. For steel, it is approximately 200 GPa (29,000 ksi).

Chemical Composition:

The precise balance of alloying elements (Carbon, Manganese, Silicon, Phosphorus, Sulfur, Copper, etc.) determines the steel's mechanical properties, weldability, and corrosion resistance. For instance, lower carbon content improves weldability, while higher manganese enhances strength and toughness. Specific limits are set by standards to ensure consistent performance.

Dimensional Specifications:

H steel bar dimensions are standardized globally, typically defined by overall depth (H), flange width (B), web thickness (t_w), and flange thickness (t_f). These dimensions influence the section's weight per meter (kg/m) and its moment of inertia, which is vital for structural calculations. For example, a 1 inch steel bar in this context might refer to a small H-beam or a specific dimension component used in detailing.

Table 1: Typical Mechanical Properties of Common H Steel Bar Grades (Example Data)

| Property | ASTM A36 | ASTM A992 | EN S275JR | EN S355JR |

|---|---|---|---|---|

| Yield Strength (min) | 250 MPa (36 ksi) | 345 MPa (50 ksi) | 275 MPa (40 ksi) | 355 MPa (51 ksi) |

| Tensile Strength | 400-550 MPa (58-80 ksi) | 450-620 MPa (65-90 ksi) | 410-560 MPa (60-81 ksi) | 470-630 MPa (68-91 ksi) |

| Elongation (min) | 23% | 21% | 23% | 22% |

| Density | ~7850 kg/m³ (490 lb/ft³) | |||

| Modulus of Elasticity | ~200 GPa (29,000 ksi) | |||

Table 2: Common H Steel Bar Dimensions & Weights (Example Data - W-shapes/IPE/HEB Series)

| Standard Profile | Depth (H, mm) | Flange Width (B, mm) | Web Thickness (t_w, mm) | Flange Thickness (t_f, mm) | Weight (kg/m) |

|---|---|---|---|---|---|

| W8x10 (AISC) | 203 | 102 | 5.8 | 8.1 | 14.9 |

| IPE 200 (EN) | 200 | 100 | 5.6 | 8.5 | 22.4 |

| HEB 200 (EN) | 200 | 200 | 8.5 | 12.0 | 61.3 |

| W24x76 (AISC) | 600 | 228 | 11.9 | 18.5 | 113.1 |

These tables provide a snapshot of the typical properties and dimensions. However, specific project requirements may necessitate variations in steel grade, surface treatment, or precise dimensions, all of which can be accommodated through customized manufacturing processes. The choice of the correct h steel bar profile and material grade is pivotal for optimizing structural performance and ensuring the long-term viability of any construction or industrial project.

Diverse Applications Across Key Industries

The versatility and robust performance of h steel bar make it an indispensable material across a vast spectrum of industries. Its unique structural properties allow for efficient and safe designs, catering to both heavy-duty industrial requirements and complex architectural visions. Here are some of the primary sectors where h steel bar plays a crucial role:

- Construction and Infrastructure: This is arguably the largest application area. H steel bar is extensively used as beams, columns, and girders in the construction of high-rise commercial and residential buildings, ensuring structural stability against gravity loads and lateral forces (wind and seismic). In infrastructure, it's vital for bridges (especially those with long spans), railway tracks, tunnels, and elevated highways, where its high strength and durability are critical for public safety and longevity. For instance, in multi-story parking garages, these bars provide the primary structural framework.

- Industrial Plants and Warehouses: Heavy industrial facilities, factories, and large-span warehouses require robust structural frameworks to support heavy machinery, overhead cranes, and extensive roofing systems. H steel bar provides the necessary rigidity and load-bearing capacity, making it ideal for constructing industrial sheds, production halls, and storage facilities where large, clear spans are essential for operational efficiency. Its prefabrication capabilities also enable rapid construction of these large structures.

- Petrochemical and Energy Sector: In oil refineries, power plants, and chemical processing facilities, h steel bar is used for pipe racks, support structures for large vessels, platforms, and equipment foundations. The material's ability to withstand extreme temperatures, corrosive environments (when treated with appropriate coatings), and heavy vibrating loads is paramount in ensuring operational safety and reliability. The inherent strength of the h steel bar ensures the long-term integrity of these critical facilities.

- Metallurgy and Mining: Within the metallurgical industry, h steel bar forms the structural backbone for furnaces, rolling mills, heavy machinery frames, and material handling systems. In mining operations, it's used for conveyor belt supports, shaft lining, and various load-bearing structures within processing plants, where high wear resistance and load capacity are required. Its resilience in challenging, abrasive environments is highly valued.

- Water Supply and Drainage Systems: While not as immediately obvious, h steel bar is used in the construction of water treatment plants, pumping stations, and large-scale aqueducts. It provides essential structural support for large pipes, tanks, and filtration equipment, ensuring the long-term stability of critical water infrastructure. Its resistance to rust, especially with galvanization, makes it suitable for moist environments.

- Marine and Offshore Structures: In shipbuilding and the construction of offshore platforms (oil rigs, wind turbine foundations), specialized grades of h steel bar are used for their high strength, fatigue resistance, and ability to withstand harsh marine conditions. These applications often require enhanced corrosion protection and specific welding procedures.

- Mechanical Equipment and Machinery: Beyond large-scale structures, smaller dimensions of h steel bar (even analogous to a 1 inch steel bar in some contexts for specific machine parts) are employed in the fabrication of heavy-duty machinery frames, agricultural equipment, and specialized transport vehicles, where a strong, rigid framework is necessary.

Figure 2: Various structural steel shapes, including h steel bar, ready for construction applications.

In each of these applications, the selection of the appropriate h steel bar size and grade is critical. For instance, in petrochemical plants, an emphasis might be placed on specific alloy steels for high-temperature resistance, while in building construction, the focus might be on ease of welding and standard dimensions. The adaptability of h steel bar to diverse environments and functional requirements solidifies its position as a cornerstone material in modern industrial and civil engineering.

Custom Solutions and Manufacturing Capabilities for H Steel Bar

While standardized dimensions and grades of h steel bar meet a broad range of general construction needs, many complex industrial and specialized infrastructure projects demand highly customized solutions. A leading manufacturer of h steel bar must possess not only robust production capabilities but also the engineering expertise to offer tailored products and services that precisely match unique project specifications. This commitment to customization distinguishes top-tier suppliers in the market.

Tailored Product Specifications:

- Specific Steel Grades: Beyond common structural steels (A36, A992, S275, S355), projects may require higher strength steels (e.g., S460), weather-resistant steels (Cor-Ten), or even specialized low-alloy steels for particular environmental conditions or performance demands. A custom provider can source or produce these specific grades.

- Non-Standard Dimensions: While most projects utilize standard beam sizes, unique architectural designs or retrofit applications might require intermediate or exceptionally large/small dimensions for h steel bar that are not commonly stocked. This could include sections as small as a theoretical 1 inch steel bar for highly specialized light-duty applications or exceptionally deep beams for long spans.

- Precision Lengths: Custom cutting to exact lengths minimizes on-site waste and fabrication time, leading to significant cost savings and improved project efficiency. This precision reduces the need for extensive cutting and welding on the construction site.

Advanced Fabrication Services:

Leading suppliers offer a comprehensive suite of value-added fabrication services, transforming raw h steel bar into ready-to-assemble components:

- Cutting and Sawing: Precision cutting to exact lengths, including miter cuts for complex connections, using advanced band saws or plasma/laser cutting technologies.

- Drilling and Punching: Pre-drilling or punching of holes for bolted connections, reducing on-site labor and ensuring accurate alignment. CNC-controlled machines ensure high precision and repeatability.

- Welding: Pre-welding of end plates, stiffeners, or other connection elements to the h steel bar in a controlled factory environment, which ensures higher quality welds compared to field welding.

- Bending and Curving: For architectural features or specialized industrial applications, H-bars can be cold or hot bent to specific radii.

- Surface Treatment: Application of various protective coatings such as shot blasting, priming, painting, hot-dip galvanizing, or intumescent fireproofing. These treatments enhance durability, corrosion resistance, and fire safety, extending the service life of the h steel bar significantly.

Engineering Support and Consultation:

Beyond manufacturing, a true partner provides comprehensive engineering support. This includes:

- Design Optimization: Collaborating with clients to optimize designs for material efficiency and structural performance, sometimes recommending alternative h steel bar sections or grades to achieve cost savings without compromising integrity.

- Technical Feasibility Studies: Assessing the viability of complex fabrications or the use of specific steel types for unique environments.

- Logistics Planning: Developing efficient delivery schedules and transportation solutions, especially for oversized or heavy components, ensuring timely arrival at the construction site.

By offering these extensive custom solutions and expert support, a manufacturer ensures that clients receive not just a product, but a tailored solution that seamlessly integrates into their project, reducing risks, accelerating timelines, and optimizing costs. This bespoke approach to h steel bar supply is critical for projects with stringent technical demands or unique design visions.

Navigating the Market: Manufacturer Comparison and Selection Criteria for H Steel Bar

Selecting the right supplier for h steel bar is a strategic decision that profoundly impacts project success, cost-efficiency, and long-term structural integrity. The market is populated by numerous manufacturers, each with varying capabilities, quality standards, and pricing structures. A thorough evaluation based on key criteria is essential for B2B buyers and project managers.

Key Factors for Manufacturer Comparison:

- Quality Certifications and Compliance: Verify adherence to international standards such as ISO 9001 for quality management, and product-specific certifications like ASTM, EN, JIS, or CE marking. These certifications are non-negotiable indicators of a manufacturer's commitment to consistent quality and safety.

- Production Capacity and Lead Times: Assess the manufacturer's ability to meet your project's volume and schedule demands. Large-scale projects require suppliers with substantial production capacity and a proven track record of on-time delivery. Enquire about typical lead times for standard and customized h steel bar orders.

- Range of Products and Customization Capabilities: Does the supplier offer the specific grades, sizes, and profiles (including a wide range of standard and potentially custom dimensions from small sections to large beams for h steel bar) required for your project? Evaluate their flexibility in offering custom lengths, finishes, or pre-fabrication services.

- Technical Expertise and Support: A reputable manufacturer should provide robust technical support, including engineering consultation, material selection guidance, and problem-solving assistance. This is particularly valuable for complex or unique applications where standard solutions may not suffice.

- Quality Control and Testing Procedures: Inquire about their internal quality control processes, from raw material inspection to final product testing. Transparency in their testing methodologies (mechanical, chemical, NDT) builds trust and assures product reliability.

- Pricing Structure and Transparency (H Bar Steel Price): While price is a significant factor, it should not be the sole determinant. Compare the h bar steel price against the value offered, including material quality, certifications, delivery reliability, and after-sales support. Beware of abnormally low prices that might indicate compromises in quality or service. Understand their pricing models for different volumes and customization levels.

- Reputation and Client Testimonials: Research the manufacturer's market reputation. Seek client testimonials, case studies, or references from previous projects to gauge their reliability, professionalism, and customer satisfaction. A long service history and strong industry partnerships are positive indicators.

- Logistics and Supply Chain Reliability: Evaluate their logistical capabilities, especially if your project is international or in a remote location. A strong supply chain ensures smooth delivery, minimizing delays and unexpected costs.

- Environmental and Sustainability Practices: In an era of increasing environmental awareness, consider manufacturers with certifications for sustainable production, energy efficiency, and waste reduction. This aligns with corporate social responsibility and green building standards.

Table 3: Manufacturer Comparison Factors for H Steel Bar Suppliers

| Comparison Factor | Key Considerations | Impact on Project |

|---|---|---|

| Quality Certifications | ISO 9001, ASTM, EN, CE, etc. | Ensures product reliability, safety, and compliance with regulations. |

| Product Range & Customization | Variety of grades, sizes (e.g., specific 1 inch steel bar equivalent, large beams), fabrication services. | Flexibility for unique designs, reduced on-site work, optimized material use. |

| Production Capacity | Ability to meet high volume demands and deliver on schedule. | Prevents project delays, ensures timely material availability. |

| Technical Support | Engineering consultation, design optimization, problem-solving. | Better design efficiency, reduced technical risks, efficient problem resolution. |

| Pricing & Value (H Bar Steel Price) | Competitive pricing, transparent cost breakdown, long-term value. | Cost-effectiveness, budget predictability, ROI. |

| Logistics & Delivery | On-time delivery, global shipping capabilities, reliable supply chain. | Minimizes project downtime, ensures continuous workflow. |

| Customer Service & Warranty | Responsiveness, after-sales support, clear warranty terms. | Builds long-term partnerships, addresses issues promptly, protects investment. |

By meticulously evaluating manufacturers against these criteria, B2B buyers can make informed decisions, ensuring they partner with a supplier that not only provides high-quality h steel bar but also contributes significantly to the overall success and profitability of their projects.

Ensuring Reliability: Quality Assurance and After-Sales Support

For critical structural components like h steel bar, product reliability is paramount. This reliability is not merely a consequence of manufacturing prowess but is deeply rooted in comprehensive quality assurance protocols and robust after-sales support. A reputable supplier understands that their responsibility extends beyond the point of sale, encompassing the entire lifecycle of the product and its integration into the client's project.

Rigorous Quality Assurance (QA) Processes:

- Raw Material Verification: Every batch of incoming raw materials (billets/blooms) undergoes stringent chemical composition analysis and physical inspection to ensure they meet the precise specifications for the target h steel bar grade. This first step prevents defects from propagating down the line.

- In-Process Quality Control: During hot rolling, continuous monitoring of temperature, pressure, and dimensions ensures consistent shaping and metallurgical properties. This includes real-time laser measurements for dimensional accuracy and thermal imaging for temperature uniformity.

- Post-Production Testing: Finished h steel bar sections are subjected to a battery of tests:

- Mechanical Testing: As detailed previously, this includes tensile, yield, elongation, and impact tests performed on samples from each production lot to verify load-bearing capacity and ductility.

- Dimensional Accuracy Checks: Precise measurements using calipers, laser gauges, and optical scanners to ensure the H-section's depth, flange width, web thickness, and straightness conform to industry standards (e.g., ASTM A6/A6M, EN 10034) and client specifications.

- Surface Quality Inspection: Visual and sometimes automated optical inspections for surface defects such as cracks, laminations, or excessive scale.

- Non-Destructive Testing (NDT): For critical applications, ultrasonic testing (UT) may be performed to detect internal flaws, voids, or inclusions within the h steel bar that are not visible externally.

- Traceability: Each h steel bar is marked and traceable back to its original heat number and production batch, allowing for full accountability and quick resolution in case of any post-delivery issues.

Certifications and Compliance:

Beyond internal QA, adherence to external certifications is a hallmark of a trustworthy manufacturer:

- ISO 9001: Certification for Quality Management Systems, demonstrating a commitment to consistent processes and customer satisfaction.

- Product-Specific Standards: Compliance with relevant American (ASTM, AISC), European (EN, Eurocodes), Japanese (JIS), or other regional standards ensures the h steel bar is suitable for international projects.

- CE Marking: Essential for products destined for the European market, indicating conformity with health, safety, and environmental protection directives.

Robust After-Sales Support:

A commitment to customer satisfaction extends far beyond delivery. Key elements of effective after-sales support include:

- Technical Consultation: Ongoing access to engineering experts for advice on fabrication, installation, welding procedures, or addressing unforeseen challenges during construction.

- Warranty and Guarantee: Clear and comprehensive warranty policies covering material defects and manufacturing flaws, providing clients with peace of mind and protection for their investment in h steel bar.

- Responsive Customer Service: A dedicated support team capable of promptly addressing inquiries, resolving issues, and facilitating any necessary reorders or modifications.

- Logistics and Delivery Management: Transparent communication regarding shipping status, customs clearance (for international orders), and effective problem-solving for any logistical disruptions to ensure materials arrive safely and on time.

- Site Support: In some cases, for large or highly complex projects, manufacturers may offer on-site technical support to ensure proper handling and installation of their h steel bar products.

By prioritizing these elements, a manufacturer of h steel bar not only delivers a superior product but also builds enduring relationships based on trust, reliability, and mutual success. This holistic approach minimizes project risks, reduces downtime, and ultimately enhances the reputation and profitability for all stakeholders.

Frequently Asked Questions (FAQ) about H Steel Bar

To provide further clarity and address common concerns, here are answers to frequently asked questions regarding h steel bar:

Q1: What are the primary advantages of using h steel bar over other structural profiles like I-beams or channels?

H steel bar (often referred to as Wide Flange beams in North America or HEB/HEA in Europe) has wider and typically thicker flanges compared to traditional I-beams (like S-beams or IPE profiles), which often have narrower flanges and tapered edges. This wider flange provides greater lateral stability and significantly higher moment of inertia, making h steel bar more efficient for carrying heavy loads, especially in bending and axial compression (as columns). Channels, on the other hand, are typically used for lighter applications or as secondary framing elements.

Q2: How does the h bar steel price vary, and what factors influence it?

The h bar steel price is influenced by several factors:

- Raw Material Costs: Fluctuations in iron ore, coal, and scrap steel prices directly impact production costs.

- Steel Grade: Higher strength or specialized alloy steel grades are generally more expensive due to complex metallurgy and additional alloying elements.

- Dimensions and Weight: Larger and heavier sections typically cost more per linear meter.

- Quantity Ordered: Larger bulk orders usually qualify for better per-unit pricing.

- Customization and Fabrication: Services like custom cutting, drilling, welding, or special surface treatments (e.g., galvanizing) add to the final price.

- Market Demand and Supply: Global and regional supply-demand dynamics significantly influence pricing.

- Transportation Costs: Freight expenses vary based on distance, mode of transport, and fuel prices.

Q3: Can h steel bar be used in corrosive environments, and what treatments are available?

Yes, standard carbon steel h steel bar can be used in corrosive environments, but it requires appropriate protective treatments. Common treatments include:

- Hot-dip Galvanizing: A process where steel is immersed in molten zinc, creating a durable, sacrificial coating that protects against rust.

- Epoxy Coatings/Paints: Various industrial paints and coatings can provide excellent protection against chemical exposure and moisture.

- Weathering Steel (Cor-Ten): A special type of steel that forms a stable, rust-like appearance after exposure to weather, eliminating the need for painting.

Q4: What is the typical lead time for ordering h steel bar?

Lead times for h steel bar can vary widely depending on the quantity, required grade and dimensions, level of customization, and current production schedules. For standard, readily available sections, lead times might range from 1-3 weeks. For custom-fabricated or very large orders, it could extend to 4-8 weeks or even longer. It's crucial to confirm lead times with your supplier during the quoting process to align with your project timeline. Expedited options may be available at an additional cost.

Q5: Is a 1 inch steel bar a common size for H-sections? What are its applications?

While '1 inch steel bar' might commonly refer to a small solid round or square bar, in the context of H-sections, it would imply a very small H-beam (e.g., a W4x1.3 or similar, where 4 inches is approximately 100mm, or a specific light-duty European section that might be ~1 inch in one dimension). Such small H-sections are less common for primary structural applications in buildings or heavy industry. However, they could be used in specialized applications such as:

- Lightweight framing for non-load-bearing partitions.

- Machine components or frames where miniature but rigid profiles are needed.

- Architectural detailing or decorative elements.

- Support for small equipment or conduits in industrial settings.

Conclusion: The Enduring Value of H Steel Bar in Modern Engineering

The journey through the intricate world of h steel bar underscores its paramount importance as a foundational material in contemporary construction and heavy industry. From its meticulously controlled manufacturing process, ensuring precise dimensions and robust mechanical properties, to its widespread application across diverse sectors like petrochemicals, metallurgy, and civil infrastructure, the h steel bar consistently proves its superior value. Its inherent advantages—high strength-to-weight ratio, excellent load-bearing capacity, seismic resilience, and ease of fabrication—translate directly into safer, more efficient, and more sustainable projects.

As global development continues to accelerate, driven by urbanization and the demand for resilient infrastructure, the role of high-quality structural steel components like the h steel bar will only grow. Strategic decision-making in procurement, guided by an understanding of technical parameters, custom solutions, and rigorous quality assurance, is crucial for optimizing project outcomes and long-term asset performance. Partnering with a manufacturer that not only offers competitive h bar steel price but also demonstrates unwavering commitment to quality, technical support, and timely delivery is indispensable for success.

Ultimately, the investment in high-grade h steel bar is an investment in the longevity, safety, and efficiency of your projects, ensuring that the structures built today will stand robustly for generations to come, symbolizing engineering excellence and reliability.

References

- American Institute of Steel Construction. (2016). Specification for Structural Steel Buildings (ANSI/AISC 360-16). Chicago, IL: AISC.

- European Committee for Standardization. (2004). Eurocode 3: Design of steel structures – Part 1-1: General rules and rules for buildings (EN 1993-1-1). Brussels, Belgium: CEN.

- ASTM International. (2020). Standard Specification for General Requirements for Rolled Structural Steel Bars, Plates, Shapes, and Sheet Piling (ASTM A6/A6M-20). West Conshohocken, PA: ASTM International.

- ASM International. (2011). ASM Handbook, Volume 1: Properties and Selection: Irons, Steels, and High-Performance Alloys. Materials Park, OH: ASM International.

- The World Steel Association. (2023). Steel Statistical Yearbook. Brussels, Belgium: World Steel Association.

- White, D. W., & Fisher, J. M. (2014). Guide to Stability Design Criteria for Metal Structures (6th ed.). Hoboken, NJ: John Wiley & Sons.

- Gere, J. M., & Goodno, B. J. (2012). Mechanics of Materials (8th ed.). Cengage Learning.

- ISO (International Organization for Standardization). (2015). Quality management systems – Requirements (ISO 9001:2015). Geneva, Switzerland: ISO.