- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

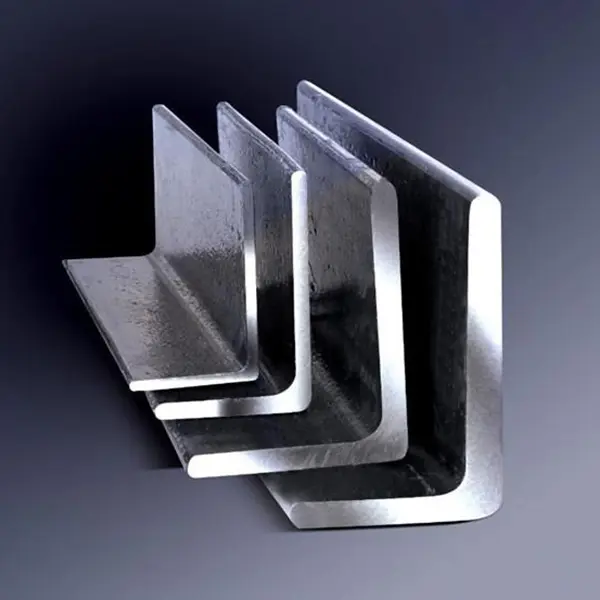

High-Quality Angle Bars for Sale - Steel & Aluminum Types

The Versatility and Demand of Angle Bars in Industrial Applications

Angle bars, characterized by their L-shaped cross-section, are fundamental structural components widely utilized across diverse industrial sectors. Their inherent strength-to-weight ratio and ease of fabrication make them indispensable in construction, manufacturing, and heavy engineering projects. The global market for structural steel, including angle bars, is experiencing steady growth, driven by escalating infrastructure development and industrial expansion, particularly in emerging economies. This sustained demand underscores the critical importance of reliable suppliers offering high-quality angle bar for sale, capable of meeting stringent performance and dimensional specifications. Understanding the intricate details from material composition to application advantages is crucial for B2B decision-makers seeking optimal solutions for their projects.

The demand for these versatile profiles spans industries such as petrochemicals for pipe racks, renewable energy for solar panel mounts, and marine engineering for vessel construction. The selection of the right angle bar significantly impacts structural integrity, cost-efficiency, and long-term operational performance. Factors like material grade (e.g., carbon steel, stainless steel, alloy steel), manufacturing precision, and adherence to international standards are paramount. Our focus here is to provide a comprehensive technical overview, guiding you through the essential aspects of angle bar selection and procurement, ensuring you make informed decisions for your specific industrial requirements.

Understanding Angle Bar Manufacturing: A Detailed Process

The production of angle bars involves a meticulous manufacturing process to ensure consistent quality and dimensional accuracy. Primarily, angle bars are produced through hot rolling, a process that involves heating steel billets to high temperatures (typically above 1,000°C) and then passing them through a series of rollers. This rolling action progressively forms the L-shaped cross-section, reducing the material's thickness while increasing its length. The choice of raw material, often carbon steel (like ASTM A36, Q235, S275JR) or various grades of stainless steel (e.g., 304, 316), is critical and depends on the intended application's environmental conditions and load requirements.

Following the hot rolling stage, the angle bars undergo cooling, straightening, and cutting to the desired lengths. Further processing, such as galvanization for enhanced corrosion resistance, painting, or punching/drilling for specific fastening requirements, may also be applied. Quality control is integrated throughout the entire manufacturing chain, from material sourcing to final inspection. Strict adherence to international standards like ISO 9001 for quality management, ASTM A6 for structural steel, and ANSI for specific dimensions ensures that each angle bar for sale meets rigorous performance benchmarks. Our products are subjected to non-destructive testing (NDT) methods, including ultrasonic testing and magnetic particle inspection, to detect any internal or surface imperfections, guaranteeing a robust and reliable product with an extended service life in demanding environments like petrochemical plants or water treatment facilities.

Key Technical Parameters and Specifications

When selecting an angle bar, understanding its technical specifications is paramount. Key parameters include leg size, thickness, length, material grade, and standard compliance. Leg sizes typically range from 20x20mm up to 250x250mm, with thicknesses varying from 3mm to 35mm. The choice depends on the structural load, span, and environmental factors. For instance, in corrosive environments, stainless steel angle bar for sale would be preferred over carbon steel. Below is a table summarizing common specifications and their implications.

Beyond these, surface finish (black, galvanized, polished) and edge types (sharp or rounded) are also important considerations. Our team offers expert consultation to help clients select the precise angle bar specifications that align with their project's structural, environmental, and budgetary requirements. This detailed approach ensures optimal performance and longevity for every application where our angle bar for sale is utilized.

Diverse Angle Bar Types and Their Strategic Applications

The market offers several angle bar types, each designed for specific structural demands. The most common are equal leg angles (L-sections with identical leg lengths) and unequal leg angles (L-sections with different leg lengths). Equal angles are versatile and widely used in general construction, framework, and support structures due to their balanced properties. Unequal angles provide higher moment resistance along one axis, making them ideal for applications requiring specific directional loading or when space constraints necessitate a more compact profile. Additionally, specialized sections like the `c angle bar` (also known as channel or U-sections) are crucial for particular applications requiring specific load distribution or enclosure capabilities.

Angle bars find extensive application across various sectors. In petrochemical industries, they are indispensable for constructing sturdy pipe racks, equipment supports, and access platforms, where their robust nature ensures safety and durability in harsh, often corrosive, environments. For metallurgy, they form critical components in conveyor systems, furnace structures, and machinery frames. In water supply and drainage systems, stainless steel angle bars are crucial for constructing resilient grates, support frames for tanks, and structural elements within treatment plants, offering superior resistance to chemical corrosion and ensuring long-term integrity. Their versatility also extends to infrastructure projects, including bridge construction, railway components, and electrical transmission towers, where precision and strength are paramount.

Choosing the appropriate angle bar types and material directly impacts the project's overall efficiency and lifespan. For instance, using galvanized steel angles in outdoor or damp conditions significantly enhances corrosion resistance, reducing maintenance costs and ensuring prolonged structural integrity, thereby offering long-term cost savings and improved operational reliability.

Figure 1: Versatile applications of angle bars in industrial frameworks.

Technical Advantages of High-Quality Angle Bars

Investing in high-quality angle bar for sale provides several distinct technical advantages that translate into significant long-term benefits for industrial projects. Superior material grades and precise manufacturing processes ensure optimal structural integrity, allowing for higher load-bearing capacities and greater resistance to deformation under stress. This robustness minimizes the risk of structural failure, enhancing safety and extending the operational lifespan of the entire system. For example, in a heavy-duty industrial conveyor system, well-engineered angle bars reduce deflection and vibration, leading to smoother operation and less wear and tear on machinery, which contributes to lower energy consumption and reduced maintenance needs.

Furthermore, the anti-corrosion properties of specific angle bar materials, such as hot-dip galvanized carbon steel or various grades of stainless steel, are crucial in aggressive environments. This enhanced corrosion resistance significantly prolongs the service life of structures in chemical plants, offshore platforms, or wastewater treatment facilities, where exposure to moisture, chemicals, and extreme temperatures is common. By resisting rust and degradation, these materials contribute to a lower total cost of ownership over the structure's lifetime, reducing the need for frequent repairs or replacements. The inherent strength and dimensional stability of our angle bars also support better integration with other components, simplifying assembly and reducing overall construction time and labor costs.

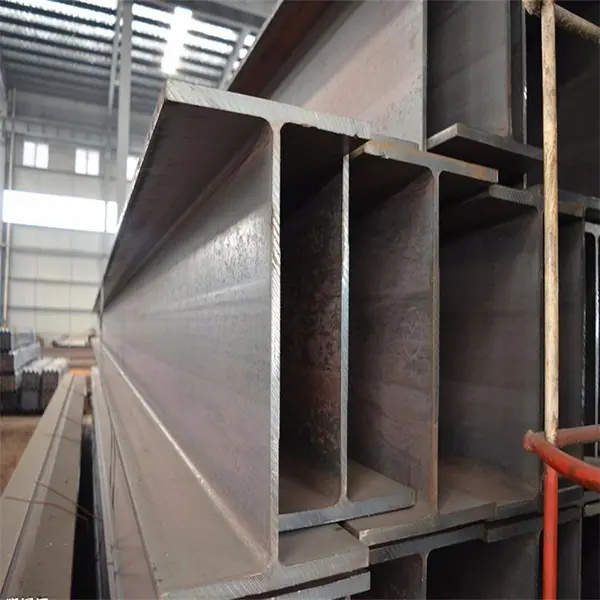

Navigating the Market: Manufacturer Comparison & Customization Solutions

The market for angle bar for sale is competitive, with numerous manufacturers offering various qualities and services. When evaluating suppliers, it is crucial to look beyond just price. Key factors include the manufacturer's adherence to international quality standards (e.g., ISO 9001, CE marking), their service history, and their capacity for specialized fabrication. A reputable manufacturer will provide comprehensive material certifications (MTCs), showcasing the chemical composition and mechanical properties of their products. Our company boasts over 20 years of experience in the steel product sector, working with industry leaders in oil & gas, infrastructure, and renewable energy, which underscores our deep understanding of client requirements and our commitment to quality.

Beyond standard offerings, customization solutions are increasingly vital for unique project demands. We provide extensive customization options for angle bars, including specific lengths, non-standard leg dimensions, custom drilling, punching, and various surface finishes such as hot-dip galvanizing, painting, or powder coating. Our advanced CNC machining capabilities ensure precise fabrication, meeting even the most intricate design specifications. Whether it's a specialized alloy for high-temperature applications or an unusual `c angle bar` dimension for a complex structural design, our engineering team collaborates closely with clients to develop tailored solutions that optimize performance and fit within project timelines and budgets. This bespoke approach minimizes on-site modifications, leading to faster project completion and reduced labor costs.

Figure 2: Custom fabrication capabilities for diverse angle bar needs.

Real-World Application Cases and Customer Feedback

Our angle bar for sale products have been integral to numerous high-profile projects globally, demonstrating their reliability and performance in demanding environments. For instance, in a major oil refinery expansion project in the Middle East, our galvanized angle bars were selected for constructing intricate pipe support structures due to their superior corrosion resistance and high strength, enduring the harsh desert climate and chemical exposure. The project engineers noted significant reductions in on-site fabrication time thanks to the precise dimensions and ease of welding of our products.

Another notable case involved providing specialized stainless steel angle bars for a new wastewater treatment facility in Southeast Asia. The client, a leading engineering firm, required materials capable of withstanding constant exposure to corrosive chemicals and moisture. Our 316L stainless steel angle bars provided the necessary durability and long-term integrity, minimizing maintenance requirements and ensuring the facility's operational continuity. Client feedback consistently highlights our consistent product quality, timely delivery, and responsive technical support. "The angle bars supplied by [Our Company Name] exceeded our expectations in terms of dimensional accuracy and material quality, which was critical for our complex structural designs," stated a project manager from a major European construction group, emphasizing the seamless integration of our components into their workflow. These testimonials underscore our commitment to delivering not just a product, but a reliable solution that contributes directly to project success.

Ensuring Your Investment: Quality Assurance & Support

At the core of our operations is an unwavering commitment to quality assurance, ensuring that every angle bar for sale meets the highest industry benchmarks. Our quality control system is certified to ISO 9001, encompassing rigorous checks at every stage, from raw material procurement to final product inspection. Each batch undergoes comprehensive testing, including chemical analysis, mechanical property tests (tensile strength, yield strength, elongation), and non-destructive tests (ultrasonic, eddy current, magnetic particle inspection) to guarantee material integrity and dimensional precision. We provide full traceability for all products, allowing clients to verify the origin and quality specifications of their purchased angle bars, fostering complete transparency and confidence.

Our commitment extends beyond product quality to comprehensive customer support. We understand the critical nature of project timelines; therefore, we offer reliable delivery cycles tailored to meet specific project schedules, facilitated by efficient logistics and global distribution networks. All our angle bars come with a robust warranty, providing peace of mind and demonstrating our confidence in the longevity and performance of our products. Our dedicated customer service team is available to provide technical assistance, clarify specifications, and address any post-sales queries promptly. From initial consultation to after-sales support, we partner with our clients to ensure a seamless experience and successful project outcomes.

Figure 3: Rigorous quality checks ensuring reliable angle bar performance.

Frequently Asked Questions (FAQ)

-

Q1: What are the common material grades for angle bar for sale and their applications?

A1: Common grades include ASTM A36 (general structural), Q235 (Chinese standard for general use), S275JR (European standard for structural applications), and stainless steel grades like SS304 and SS316. SS304 is ideal for general corrosion resistance, while SS316 offers superior resistance in marine or highly corrosive chemical environments due to its molybdenum content. Choosing the correct grade is vital for the longevity and performance of the structure in its specific operating environment, impacting factors like fatigue resistance and overall cost-efficiency.

-

Q2: How do you ensure the dimensional accuracy of angle bars?

A2: We employ advanced hot rolling processes followed by precision straightening and cutting. Our manufacturing lines utilize automated measurement systems and stringent quality control protocols, including calibrated gauges and laser scanning, to ensure that the leg sizes, thickness, and straightness meet or exceed international standards like ASTM A6 and EN 10056. This meticulous attention to detail minimizes deviations and ensures that our angle bar for sale components fit precisely into your structural designs.

-

Q3: Can you provide customized lengths or pre-fabricated angles?

A3: Yes, we offer extensive customization services. Beyond standard lengths, we can provide precise custom cuts to minimize waste and on-site fabrication. Our facilities are equipped for advanced pre-fabrication, including drilling, punching, and welding of angle bars into more complex assemblies according to client blueprints. This service streamlines your project workflow, reduces labor costs, and ensures higher precision in the final structure, making our angle bar for sale adaptable to diverse project requirements.

Conclusion

The selection of the right angle bar for sale is a critical decision that impacts the safety, efficiency, and longevity of industrial and structural projects. From understanding the intricate manufacturing processes and technical parameters to recognizing the strategic advantages of high-quality materials, informed procurement is key. Our commitment to providing superior `angle bar types`, coupled with comprehensive technical support, customization capabilities, and rigorous quality assurance, positions us as a trusted partner for B2B clients worldwide. By prioritizing precision, durability, and adherence to international standards, we ensure that our angle bars contribute to the success and resilience of your most demanding applications.

References

- American Society for Testing and Materials (ASTM) Standards for Structural Steel.

- International Organization for Standardization (ISO) 9001: Quality Management Systems – Requirements.

- European Standard (EN) 10056: Hot-rolled structural steel equal and unequal leg angles.

- The Steel Construction Institute (SCI) Publications on Structural Steel Design.

- The American Institute of Steel Construction (AISC) Manual of Steel Construction.