- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

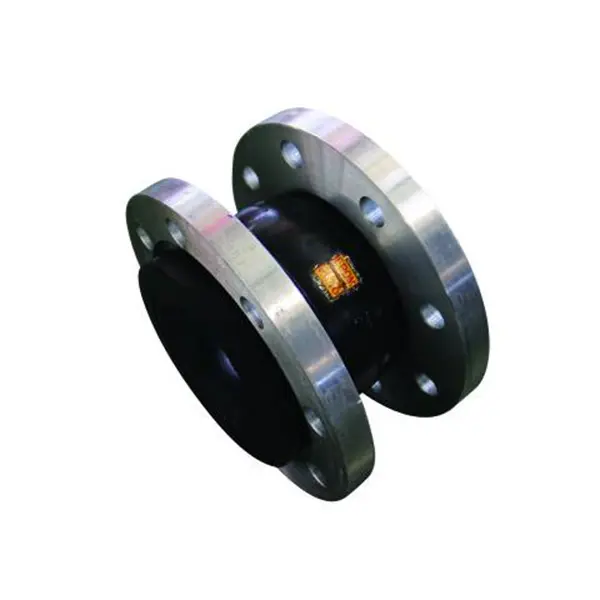

High-Quality Flanged Rubber Expansion Joint for Piping Systems

About Hebei Gain Trading Co.,Ltd.

Hebei Gain Trading Co.,Ltd. is a global industry leader manufacturing and supplying high-quality flanged rubber expansion joint solutions. With a strong commitment to technology, quality, and customer satisfaction, we serve clients worldwide.

Visit Our Website

Email: hbgain@aliyun.com | Phone/WhatsApp: 86-15128155291

Address: Malleable Iron Zone, Shijiazhuang, Hebei, China

Overview of Flanged Rubber Expansion Joint

The flanged rubber expansion joint is a vital component within pipeline and mechanical engineering. Designed to absorb vibrations, accommodate axial, lateral and angular movements, and reduce noise, these joints are extensively used in power plants, water works, HVAC, chemical processing, marine industries, and more. Related products like flexible rubber expansion joint and single sphere rubber expansion joint address specific engineering challenges, combining flexibility, durability, and corrosion resistance.

Modern pipeline systems rely heavily on these advanced solutions to ensure longevity and optimal performance.

Product Introduction: Rubber Expansion Joint

Short Description & Technical Features

- Supply range up to DN4000 for large scale projects.

- Large diameter joints must use limiters/control units for safety and stability.

- OEM production as per drawing accepted; standard flanges GB/T9115.1-2000 and others (ANSI, DIN, BSEN, NF, EN, JIS, ISO) available on request.

- Rubber body options: NR, EPDM, Neoprene, IIR, NBR, FKM, and more.

- Critical for overhead water systems: above DN200 must have fixed supports/control units.

- All matching flanges made to valve or GB/T9115.1(RF) specifications.

- Refer to our official product page for full specs: flanged rubber expansion joint Technical Details

Market & Industry Trends (2024): The Rise of Flanged Rubber Expansion Joint

Global demand for flanged rubber expansion joint is witnessing substantial growth. Accelerated urbanization, infrastructure renewal, and stricter industrial safety codes drive adoption rates upwards. According to Engineering.com and Pumps & Systems Magazine, the flexible rubber expansion joint sector shows a CAGR of 5-7% for 2024–2026 (Source: Valuates Reports).

Technical Parameters Table: Flanged Rubber Expansion Joint

| Parameter | Specification | Industry Notes |

|---|---|---|

| Size Range | DN25 ~ DN4000 | Customizable for large pipelines |

| Pressure Rating | PN6, PN10, PN16, 150psi, 300psi | Wide pressure/temperature applicability |

| Rubber Material | NR, EPDM, NBR, Neoprene, IIR, FKM | Application matched for chemical, water, HVAC etc. |

| Flange Material | Carbon Steel, Stainless Steel, Ductile Iron | Supports various standard specifications |

| Movement Capability | Axial: ±25mm, Lateral: ±15mm, Angular: ±10° | High deformation tolerance |

| Temperature Range | -30°C ~ +130°C | Material dependent |

| Design Standard | GB/T9115.1-2000, ANSI, DIN, JIS, ISO | Multiple global norms |

Data Visualization — Technical Index Trends

Technical Parameter Comparison

Material Market Share (2023-2024)

Yearly Demand Growth Curve

Application Scenarios & Use Cases

- Water Supply & Treatment: Ensures leak-proof connections in potable, desalination, and wastewater plants. Large diameter (flanged rubber expansion joint) systems crucial in mainline transitions.

- HVAC Systems (Heating/Ventilation/Air Conditioning): Essential for sound and vibration isolation for high-rise and industrial complexes.

- Power Generation & Energy Facilities: Buffering thermal expansion/contraction cycles and equipment displacement.

- Chemical Processing: Resistant to aggressive chemicals, acids, and alkalis – requiring EPDM, FKM customized joints.

- Marine & Shipbuilding: Protection against hull or engine vibration and saline corrosion.

- Fire Protection Networks: Reliable performance in in-building and municipal hydrant pipelines.

- OEM/Custom Machinery: Special drawing or parameter flexible rubber expansion joint designs available on request.

Advantages and Comparative Analysis

- Superior Flexibility: Absorbs multi-directional vibration, offering higher pipeline system stability over rigid connections.

- Corrosion & Weather Resistance: Wide rubber and flange material selection, compatible even in extreme environments.

- Custom Engineering: Large-diameter designs (up to DN4000); support for control units, OEM, or special flange standards, matched to customer requirements.

- Longevity & Maintenance: Fewer failures, longer service intervals, and cost-effective in high-usage plants.

- Safety Compliance: All products meet GB, ANSI, DIN, JIS, ISO, and other international safety norms.

Expert FAQ: Flanged Rubber Expansion Joint Technology

A: Standard elastomers are NR (Natural Rubber), EPDM, NBR, Neoprene, IIR, and FKM. Material selection depends on fluid type, temperature, and pipeline conditions.

Q2: What are the typical size and pressure ranges?

A: Sizes vary from DN20–DN4000; typical pressure classes are PN6, PN10, PN16, and up to 300psi.

Q3: How is installation torque and alignment ensured?

A: Follow manufacturer torque tables for bolts (refer to flanged rubber expansion joint). Pipe alignment must be within joint tolerance to prevent overstress.

Q4: When are limiters or control units required?

A: For overhead piping (>DN200) or high-pressure jobs, control units are essential to prevent overextension and enhance safety.

Q5: Can joints be customized for specific chemical resistance?

A: Yes, material like EPDM, FKM, or special compounds are used for harsh acid/alkali resistance as per application.

Q6: Which flange standards are supported?

A: Standards include GB/T9115.1-2000, ANSI, DIN, BSEN, JIS, ISO, and custom flanges as per client specs.

Q7: What is the main difference between single sphere and double sphere rubber expansion joints?

A: Single sphere rubber expansion joint offers a more compact profile and better vibration damping, while double sphere types provide greater movement absorption and pressure resilience.

Best Practices for Selection, Installation & Maintenance

- Ensure compatibility of joint material and flange standard with conveying fluid and operating environment.

- Install fixed supports or control units for overhead or high-load piping systems.

- Regularly inspect for rubber surface aging, flange bolt loosening, or deformation. Replace promptly if any fault detected.

- Use torque wrenches calibrated as per pipe size and joint material.

- Review manufacturer’s data sheet and technical support for unique or OEM configurations.

Why Choose Hebei Gain Trading Co.,Ltd.?

- Global Authority: Decades of export experience and client trust worldwide.

- Strict Quality Control: ISO-certified, every flanged rubber expansion joint tested to the highest standards.

- Technical Expertise: Help with sizing, OEM drawings, and installation support.

- Complete Compliance: Multi-standard flange and elastomer selection, suiting every regional project spec.

- Reliable Service: Fast inquiry response times, full documentation, and shipment support.

Hebei Gain Trading Co.,Ltd.

Website: www.szpipefitting.com

Email: hbgain@aliyun.com | Phone/WhatsApp: 86-15128155291

Address: Malleable Iron Zone, Shijiazhuang, Hebei, China

Conclusion

With expanding industrial infrastructure, the demand for flanged rubber expansion joint and related products such as flexible rubber expansion joint and single sphere rubber expansion joint is set to accelerate. By partnering with Hebei Gain Trading Co.,Ltd., clients are guaranteed top-tier quality, technical expertise, and on-time support for every project.

For more research and best engineering practices, refer to:

- engineering.com – Industry insights on pipe system innovation

- Pumps & Systems Magazine – Best practices in flexible connections

- Valuates Reports – Global and regional market trends 2024

- ASCE Library: Expansion Joint Technology

- ResearchGate: Performance & Application of Rubber Expansion Joints

- flanged rubber expansion joint Spec – Hebei Gain Trading Co.,Ltd.