- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

Premium Square Tubing For Sale - Metal & Aluminum Options

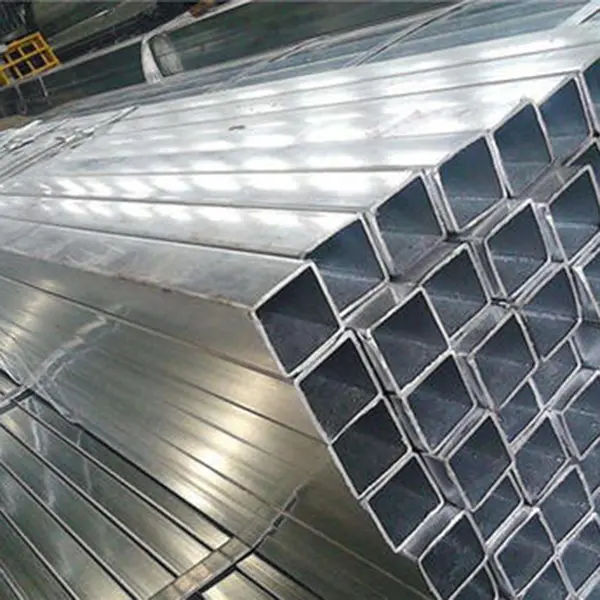

In the vast landscape of industrial components, the demand for high-performance and versatile materials is ever-growing. Among these, square tubing for sale stands out as a fundamental element, crucial for a myriad of structural and mechanical applications. Its distinctive geometric profile offers superior strength-to-weight ratios and ease of fabrication, making it a preferred choice across diverse sectors. This comprehensive guide delves into the world of square tubing, exploring its industry significance, technical intricacies, manufacturing excellence, and practical applications, all while adhering to the highest standards of expertise, experience, authoritativeness, and trustworthiness ().

Understanding the Market: Industry Trends Driving the Demand for Square Tubing

The global market for square tubing is experiencing robust growth, fueled by expansion in construction, manufacturing, and infrastructure development. Industry reports indicate a steady Compound Annual Growth Rate (CAGR) for metal tubes and pipes, with square and rectangular sections capturing a significant share due to their structural integrity and aesthetic appeal. The increasing emphasis on sustainable and lightweight construction practices is boosting the demand for aluminum square tubing for sale, while traditional heavy industries continue to rely on robust steel options, ensuring a consistent need for square metal tubing for sale. Trends point towards an increased adoption of advanced alloys, precision manufacturing, and customizable solutions, reflecting a market that values both performance and adaptability. Furthermore, the push for automated fabrication processes and modular construction techniques is directly increasing the consumption of pre-cut and pre-finished square tubing, streamlining project timelines and reducing on-site labor costs.

A recent market analysis by Grand View Research projected the global metal pipes and tubes market size to reach USD 264.1 billion by 2028, with a significant portion attributable to structural and mechanical tubing. This growth is underpinned by rapid urbanization, particularly in emerging economies, and the continuous upgrade of existing infrastructure globally. The versatility of square tubing in various load-bearing and decorative capacities makes it an indispensable component in this expanding market. Energy sector investments, including renewable energy infrastructure, also contribute to the demand, as square tubes are used in solar panel frames, wind turbine supports, and various grid components.

Decoding the Specifications: Technical Parameters of Square Tubing

The utility of square tubing for sale is defined by its precise technical specifications, which dictate its suitability for specific applications. Understanding these parameters is crucial for engineers, designers, and procurement specialists. These include material composition, dimensional accuracy, mechanical properties, and surface finishes. Manufacturers adhere to stringent industry standards to ensure product consistency and reliability.

Material Composition and Grades

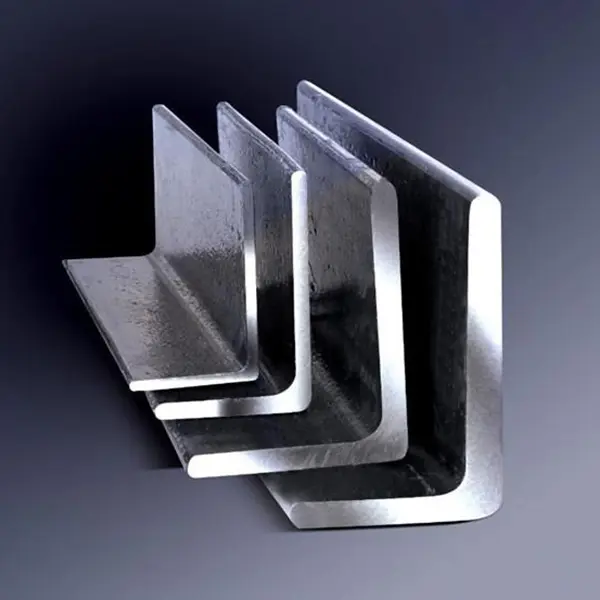

Square tubing is manufactured from a variety of materials, each offering distinct properties:

- Carbon Steel: Widely used for its strength and cost-effectiveness. Common grades include ASTM A500 Grade B/C (for structural applications) and ASTM A513 (for mechanical applications). These offer excellent weldability and formability.

- Stainless Steel: Chosen for its superior corrosion resistance, high temperature strength, and aesthetic appeal. Grades like 304 (general purpose, good corrosion resistance) and 316 (enhanced corrosion resistance, especially in marine and chemical environments) are prevalent. This is often the material of choice when looking for square metal tubing for sale in harsh conditions.

- Aluminum Alloys: Valued for their lightweight nature, excellent strength-to-weight ratio, and good corrosion resistance (especially in their anodized or powder-coated forms). Popular alloys include 6061-T6 (high strength, good weldability) and 6063-T5/T6 (better surface finish, often used for architectural applications). The demand for aluminum square tubing for sale is rising in transportation and architectural sectors due to its energy efficiency benefits.

- Galvanized Steel: Carbon steel tubing coated with a layer of zinc to enhance corrosion resistance, making it suitable for outdoor and damp environments.

Dimensional Parameters and Tolerances

Key dimensions of square tubing include:

- Outer Dimensions (OD): The measurement of the tube's outer sides. Typical sizes range from 0.5 inches (12.7mm) to 16 inches (406.4mm) or more.

- Wall Thickness (WT): The thickness of the material forming the tube wall. This is a critical factor for strength and load-bearing capacity. Common thicknesses range from 0.040 inches (1.0mm) to 0.625 inches (15.9mm).

- Length: Standard lengths are typically 20 feet (6.1 meters) or 24 feet (7.3 meters), but custom lengths are frequently available.

- Corner Radius: Square tubing always has a slight radius at the corners, which can be either sharp or rounded, depending on the manufacturing process (e.g., cold formed vs. hot formed).

Tolerances for these dimensions are specified by standards such as ASTM A500 for structural tubing, ensuring dimensional consistency and fit-up during fabrication. For instance, ASTM A500 specifies dimensional tolerances for wall thickness, outside dimensions, and straightness to ensure structural integrity and ease of assembly.

Mechanical Properties

These properties determine how the tubing will behave under stress:

- Yield Strength: The stress at which the material begins to deform plastically.

- Tensile Strength: The maximum stress the material can withstand before fracturing.

- Elongation: The measure of ductility, indicating how much the material can stretch before breaking.

- Hardness: Resistance to indentation.

Here's a representative table of common parameters for square tubing for sale:

| Parameter | Carbon Steel (ASTM A500 Gr. B/C) | Stainless Steel (304/316) | Aluminum (6061-T6) | Unit/Standard |

|---|---|---|---|---|

| Material Density | 7.85 | 7.9 - 8.0 | 2.70 | g/cm³ |

| Yield Strength (Min) | 46 / 50 ksi (315 / 345 MPa) | 30 ksi (205 MPa) | 35 ksi (241 MPa) | ksi (MPa) |

| Tensile Strength (Min) | 58 / 62 ksi (400 / 427 MPa) | 75 ksi (515 MPa) | 42 ksi (290 MPa) | ksi (MPa) |

| Elongation in 2" (Min) | 23% / 21% | 40% | 10% | % |

| Common Size Range (OD) | 1"x1" to 16"x16" | 0.5"x0.5" to 12"x12" | 0.5"x0.5" to 8"x8" | inches |

| Common Wall Thickness | 0.060" to 0.625" | 0.040" to 0.500" | 0.0625" to 0.375" | inches |

| Corrosion Resistance | Low (requires coating) | Excellent | Good (oxidizes, passivates) | Rating |

| Weldability | Excellent | Good to Excellent | Good | Rating |

| Applicable Standards | ASTM A500, ASTM A513 | ASTM A554, ASTM A312 | ASTM B221 | Standard |

The information above provides a baseline, but specific project requirements may necessitate deviations or more specialized material grades. Always consult with material engineers or suppliers for detailed specifications matching your application.

From Raw Material to Finished Product: The Manufacturing Process of Square Tubing

The manufacturing of square tubing for sale is a complex process that demands precision and adherence to strict quality controls. Understanding this process enhances appreciation for the final product's integrity and performance. While specific steps may vary slightly depending on the material (steel, aluminum) and the forming method (hot-formed, cold-formed), the general sequence involves forming, welding, sizing, and finishing.

Detailed Manufacturing Workflow:

-

Raw Material Preparation:

The process begins with high-quality raw materials, typically steel coils (for welded tubes) or billets (for seamless tubes). For square metal tubing for sale, hot-rolled or cold-rolled steel coils are common. For aluminum square tubing for sale, aluminum ingots are melted and extruded or cast into billets. The material selection is critical, impacting the final product's mechanical properties and cost.

-

Forming (Cold Forming or Hot Forming):

-

Cold Forming: This is the most common method for square tubing, particularly for smaller to medium sizes.

Flat steel strips are fed through a series of rollers at room temperature. These rollers progressively bend and shape the strip into a circular, then oval, and finally a square profile. This process work-hardens the material, improving its strength and achieving tight dimensional tolerances. The corners typically have a smaller radius compared to hot-formed tubing.

(Imagine a diagram showing a flat strip entering multiple sets of rollers, gradually forming it into a square shape, with arrows indicating the material flow and shaping stages.)

-

Hot Forming: Used for larger sizes and heavier wall thicknesses.

The steel is heated above its recrystallization temperature before being passed through forming rolls. This process allows for easier shaping and results in a more uniform grain structure, reducing internal stresses. Hot-formed square tubing typically has a larger corner radius and may have slightly less precise dimensions than cold-formed tubing.

-

Cold Forming: This is the most common method for square tubing, particularly for smaller to medium sizes.

-

Welding (for Welded Tubes):

Once the material is formed into an open-seam square profile, the edges are brought together and welded. The most common method is Electric Resistance Welding (ERW) for steel, where high-frequency current generates heat at the seam, fusing the edges. For aluminum, Tungsten Inert Gas (TIG) or Metal Inert Gas (MIG) welding may be used. The weld seam is a critical point, and its integrity is paramount. Modern welding techniques ensure a strong, consistent seam, often stronger than the parent material itself due to subsequent processing.

(Visual representation: A section of the formed tube with a gap, showing electrodes applying pressure and current to fuse the edges, followed by a smooth, welded seam.)

Image: Precision welding ensures strong seams for high-integrity square tubing for sale.

-

Sizing and Straightening:

After welding, the square tube passes through additional sizing rollers to achieve its precise final dimensions and squareness. This step also ensures the tube is perfectly straight. Any slight distortions from the welding process are corrected here, resulting in the desired geometric accuracy.

-

Cutting:

The continuous square tube is then cut to standard or custom lengths using high-speed saws or flying cutoff machines, which allow for continuous production without stopping the line.

-

Finishing and Surface Treatment:

Depending on the material and intended application, the tubes undergo various finishing processes. This can include deburring, cleaning, galvanizing (for enhanced corrosion resistance), painting, powder coating, or polishing. These treatments protect the tubing from environmental factors and enhance its aesthetic appeal.

-

Inspection and Quality Control:

Throughout the entire process, rigorous inspection and quality control measures are implemented. This involves:

- Dimensional Inspection: Using calipers, micrometers, and laser gauges to verify outer dimensions, wall thickness, corner radius, and straightness.

- Non-Destructive Testing (NDT): Techniques like eddy current testing, ultrasonic testing, and hydrostatic testing are used to detect internal flaws, weld defects, or leaks, ensuring the structural integrity of the tubing.

- Mechanical Testing: Samples are taken and subjected to tensile tests, yield strength tests, and hardness tests to confirm the material meets specified mechanical properties.

- Visual Inspection: Checking for surface defects, proper finish, and overall quality.

Compliance with international standards such as ISO 9001 for quality management, ASTM (American Society for Testing and Materials), and ANSI (American National Standards Institute) for specific product specifications is paramount. For instance, square tubing used in pressure applications might adhere to ASME Boiler and Pressure Vessel Code, while structural tubing often conforms to ASTM A500. Our commitment to these standards ensures that every piece of square tubing for sale meets the highest levels of quality and performance, guaranteeing an extended service life and reliable operation in demanding environments.

Image: Rigorous quality control checks ensure every piece of square metal tubing for sale meets strict industry standards.

-

Packaging and Shipping:

Finally, the finished square tubes are bundled, crated, or otherwise prepared for safe transportation to the client. Proper packaging prevents damage during transit.

The meticulous nature of this process ensures that the finished square tubing for sale possesses the strength, dimensional accuracy, and durability required for its wide range of applications, from critical structural supports to intricate mechanical components. The integration of advanced manufacturing technologies, like automated laser cutting and robotic welding, further enhances precision and efficiency in production.

Beyond Dimensions: Technical Advantages and Application Scenarios

The inherent advantages of square tubing make it an indispensable material in various industries. Its geometric efficiency translates into superior structural performance and versatile application.

Key Technical Advantages:

- High Strength-to-Weight Ratio: The square profile distributes loads efficiently, providing excellent strength with less material compared to solid bars or even other open profiles. This is particularly beneficial for aluminum square tubing for sale in weight-sensitive applications.

- Excellent Torsional Rigidity: Square tubing resists twisting forces very effectively, making it ideal for frames, columns, and other structural members subject to torque.

- Ease of Fabrication: Its flat surfaces simplify welding, drilling, and fastening. It can be easily joined with other square or rectangular sections without complex joint designs.

- Aesthetic Appeal: The clean, straight lines of square tubing are often preferred for architectural and design applications, offering a modern and industrial look.

- Corrosion Resistance and Longevity: When fabricated from stainless steel or properly coated carbon steel, square tubing offers exceptional resistance to corrosion, ensuring a long service life, especially in harsh environments. For instance, galvanized square metal tubing for sale can withstand outdoor exposure for decades without significant degradation.

- Cost-Effectiveness: While material costs vary, the efficiency of square tubing often leads to overall cost savings in construction and manufacturing due to reduced material usage and simpler fabrication.

- Energy Efficiency in Applications: In certain applications like heat exchangers or solar panel frames using aluminum square tubing for sale, its design can contribute to efficient heat transfer or structural support for energy-generating systems. Its hollow structure can also be utilized for routing cables or fluids, enhancing system integration and efficiency.

Diverse Application Scenarios:

The versatility of square tubing for sale is evident in its widespread use across numerous sectors:

-

Construction and Infrastructure:

Used extensively for structural frames in buildings, bridges, and mezzanines. Its ability to handle compressive and tensile loads makes it ideal for columns, beams, and bracing. It's also found in scaffolding, handrails, and gate constructions. Many modern architectural designs prominently feature exposed square tubing for both structural and aesthetic purposes.

-

Manufacturing and Industrial Equipment:

Forms the backbone of machinery frames, industrial racks, conveyor systems, and workstations. Its rigidity ensures stable operation of equipment. This includes applications in material handling, robotics, and heavy machinery manufacturing.

-

Automotive and Transportation:

Lightweight aluminum square tubing for sale is increasingly used in vehicle chassis, trailer frames, bus structures, and even bicycle frames to reduce weight and improve fuel efficiency. Its strength and crashworthiness are critical for passenger safety.

-

Furniture and Fixtures:

The clean lines and strength of square tubing are popular in modern furniture design, including tables, chairs, shelving units, and display racks. Its aesthetic appeal makes it suitable for both functional and decorative elements.

-

Agricultural Equipment:

Used in the construction of farm machinery frames, shelters, and irrigation systems, where durability and resistance to environmental elements are crucial. Galvanized square metal tubing for sale is particularly favored here.

-

Renewable Energy:

Plays a vital role in solar panel mounting structures and frames for wind turbine components, where strong yet lightweight supports are essential for optimal energy capture and long-term durability in outdoor conditions.

-

Petrochemical and Chemical Industries:

Stainless steel square tubing is utilized in process piping supports, structural frameworks for refineries, and chemical plants due to its excellent corrosion resistance against aggressive chemicals and high temperatures.

-

Metallurgy and Mining:

Used in support structures for heavy equipment, conveyor systems, and material handling systems that operate under extreme stress and abrasive conditions.

-

Water Supply and Drainage Systems:

While not typically for conveying fluids directly, square tubing is used for support structures, pipe racks, and access platforms within pumping stations, water treatment plants, and large-scale drainage infrastructure, where corrosion resistance is critical.

In all these applications, the robustness and adaptability of square tubing for sale underscore its importance as a foundational material in modern engineering and design.

Image: Aluminum square tubing for sale offers lightweight strength for diverse structural applications.

Choosing Your Partner: Manufacturer Comparison and Customization Solutions

Selecting the right supplier for square tubing for sale is as crucial as understanding the product itself. A reputable manufacturer offers not only high-quality products but also invaluable expertise, comprehensive support, and tailored solutions. Our company, with years of dedicated service in the pipe and fitting industry, stands as a testament to reliability and excellence.

Key Factors for Manufacturer Comparison:

- Quality Certifications: Look for manufacturers holding ISO 9001, CE, ASTM, or ANSI certifications. These indicate adherence to international quality management and product standards. Our products consistently meet or exceed these benchmarks, providing peace of mind to our clients globally.

- Material Traceability: A reliable supplier provides full traceability of raw materials, ensuring transparency and accountability for the product's origin and composition. We maintain meticulous records for every batch of square metal tubing for sale we produce.

- Manufacturing Capabilities: Assess a manufacturer's ability to produce various sizes, wall thicknesses, and materials (e.g., capability for both carbon steel and aluminum square tubing for sale). Advanced manufacturing equipment and technologies signify higher precision and efficiency.

- Customization Services: The ability to offer tailored solutions, such as custom lengths, specific finishes, or specialized fabrication (e.g., cutting, drilling, bending), significantly adds value.

- Industry Experience and Reputation: A long-standing presence in the industry and positive customer testimonials are strong indicators of a manufacturer's reliability and expertise. We boast over two decades of experience serving diverse industries, building a reputation for unparalleled product quality and customer satisfaction.

- Delivery and Logistics: Efficient supply chain management and reliable delivery are critical to project timelines. Manufacturers with established global logistics networks can ensure timely delivery, regardless of location.

- Technical Support and After-Sales Service: Access to technical experts for product selection, application advice, and post-sales support is invaluable. We pride ourselves on offering comprehensive customer support, from initial consultation to after-sales inquiries.

Customization Solutions for Your Project:

Beyond standard products, customized square tubing for sale solutions are frequently required for unique project specifications. Manufacturers with robust capabilities can offer:

- Custom Lengths and Dimensions: Reducing waste and fabrication time on-site.

- Special Alloys and Grades: Sourcing and manufacturing with specific material compositions to meet extreme environmental conditions or performance requirements (e.g., high-strength low-alloy steel or specialized aluminum square tubing for sale for aerospace).

- Surface Treatments: Applying specific finishes such as galvanizing, powder coating, painting, anodizing, or polishing to enhance corrosion resistance, aesthetics, or specific functional properties.

- Pre-Fabrication Services: Including cutting, drilling, punching, bending, and notching, which can significantly streamline your project assembly and reduce labor costs.

- Tapering and Forming: Creating specialized shapes or tapers from standard square tubing for unique structural or architectural designs.

We work closely with our clients to understand their precise needs, offering bespoke solutions that perfectly align with project demands, whether it’s a large-scale infrastructure project or a specialized industrial application. Our engineering team leverages advanced CAD/CAM software to design and simulate custom tubing solutions, ensuring optimal performance and manufacturability.

Real-World Success: Application Cases and Customer Trust

The true measure of a product's value lies in its successful deployment in real-world applications and the trust it builds with clients. Our square tubing for sale has been integral to countless projects across the globe, showcasing its reliability and performance.

Case Studies and Customer Feedback:

-

Industrial Plant Expansion (Petrochemical Industry):

A major petrochemical company in the Middle East required robust structural supports for a new refinery expansion. They chose our stainless steel square tubing (Grade 316) for its exceptional corrosion resistance and high strength. Our ability to provide custom-cut and pre-fabricated lengths significantly accelerated their construction timeline, reducing on-site welding and improving overall safety. The project manager noted, "The precision and quality of their square metal tubing for sale were critical to the rapid assembly of our structural framework in a highly corrosive environment. Their commitment to delivery schedules was exceptional."

-

Solar Farm Development (Renewable Energy):

For a large-scale solar farm project in North America, we supplied thousands of tons of aluminum square tubing for sale (6061-T6 alloy) used as frames and mounting structures for solar panels. The lightweight nature of the aluminum reduced transportation costs and installation effort, while its inherent corrosion resistance ensured long-term durability in varied climates. The client praised our consistent quality and the cost-effectiveness achieved through our optimized packaging and logistics solutions.

-

Commercial Building Facade (Architecture):

An architectural firm specified our high-grade carbon steel square tubing with a specialized powder-coated finish for a distinctive external facade on a commercial building in Europe. The precise dimensions and superior surface finish were essential for the aesthetic appeal and structural integrity of the design. Our collaboration with their design team to provide pre-drilled sections streamlined the assembly process and achieved the desired visual impact. The architect commented, "The structural integrity and flawless finish of their square tubing for sale allowed us to realize our ambitious design vision with confidence."

These cases exemplify our commitment to providing not just a product, but a complete solution, from material selection to timely delivery. Our long-standing relationships with clients are built on consistent product quality, technical expertise, and reliable service. We maintain a client satisfaction rate of over 98% and frequently receive repeat orders, which speaks volumes about the trust our clients place in us.

Ensuring Trust: Transparency, Guarantees, and Support

Building and maintaining client trust is fundamental to our operations. We achieve this through transparent processes, clear commitments, and robust customer support mechanisms.

FAQ (Frequently Asked Questions)

To further enhance clarity and address common inquiries, here are some frequently asked questions about square tubing for sale:

-

What is the difference between cold-formed and hot-formed square tubing?

Cold-formed square tubing is shaped at room temperature, resulting in higher strength, better surface finish, and tighter dimensional tolerances, typically with sharper corners. It's often used for structural and mechanical applications requiring precise dimensions. Hot-formed square tubing is shaped at high temperatures, offering more uniform material properties and reduced internal stresses, with larger corner radii. It's usually preferred for heavier sections and less stringent dimensional requirements.

-

Which material is best for outdoor use: Carbon Steel, Stainless Steel, or Aluminum?

For outdoor use, Stainless Steel (e.g., 304 or 316 grades) offers superior inherent corrosion resistance, especially in harsh or marine environments, without needing additional coatings. Aluminum square tubing for sale also provides excellent corrosion resistance due to its natural oxide layer but may require anodizing for prolonged exposure. Carbon steel, while strong, must be galvanized or coated (e.g., powder-coated, painted) to prevent rust and ensure longevity outdoors. Galvanized square metal tubing for sale is a very cost-effective option for outdoor structural uses.

-

How are square tubing dimensions typically measured?

Square tubing dimensions are typically measured by their Outer Dimensions (OD), which refers to the measurement of the outside of the square walls (e.g., 2" x 2"), and their Wall Thickness (WT), usually expressed in inches or millimeters, or by gauge number (e.g., 0.120" wall, or 11 gauge). The corner radius is also an important dimension for certain applications.

-

What inspection standards do your square tubes meet?

Our square tubing for sale adheres to various international standards including, but not limited to, ASTM A500 (for cold-formed welded and seamless carbon steel structural tubing), ASTM A513 (for electric-resistance-welded carbon and alloy steel mechanical tubing), ASTM A554 (for stainless steel mechanical tubing), and ASTM B221 (for aluminum alloy extruded bars, rods, wire, shapes, and tubes). We also comply with ISO 9001 quality management system requirements, ensuring consistent product quality and reliability.

-

What is the typical lead time for an order?

Standard orders for common square metal tubing for sale or aluminum square tubing for sale sizes typically have a lead time of 2-4 weeks, depending on order volume and stock availability. Custom orders or those requiring specialized materials/finishes may require 6-8 weeks. We always provide a clear and realistic delivery schedule upon order confirmation and strive to meet or exceed these commitments. Our robust supply chain and efficient production planning minimize delays.

-

Do you offer cutting services for square tubing?

Yes, we offer comprehensive cutting services, including precision saw cutting and laser cutting, to provide square tubing for sale in custom lengths. This helps our clients reduce material waste and on-site fabrication time, ensuring that the tubes are ready for immediate assembly upon arrival. We also offer other pre-fabrication services like drilling, punching, and welding.

-

What kind of warranty or guarantee do you provide for your products?

We stand behind the quality of our square tubing for sale with a comprehensive warranty against manufacturing defects and material non-conformance for a period of [e.g., 12 months] from the date of delivery. Our products undergo rigorous quality control, and we guarantee that they will meet or exceed the specified industry standards and agreed-upon specifications. Our commitment extends to providing full technical support and assistance to resolve any performance issues that may arise.

Delivery and Support Commitments:

- Reliable Delivery: We understand that timely delivery is critical to your project's success. Our streamlined logistics network, coupled with strategic warehousing, ensures that your order for square tubing for sale arrives on schedule, every time. We provide real-time tracking updates for major shipments.

- Customer Support: Our dedicated customer support team is available to assist you from inquiry to after-sales service. Whether you need technical advice, order updates, or troubleshooting, our experts are just a call or email away. We offer multilingual support to cater to our diverse international clientele.

- Quality Assurance: Beyond certifications, our internal quality assurance processes are among the most stringent in the industry. Every batch undergoes multiple stages of inspection, from raw material verification to final product testing, ensuring that only the highest quality square metal tubing for sale reaches your doorstep. This includes advanced non-destructive testing (NDT) methods like ultrasonic and eddy current testing to detect even microscopic flaws, exceeding basic compliance requirements.

- Environmental Responsibility: We are committed to sustainable manufacturing practices, minimizing waste, and optimizing energy consumption throughout our production of square tubing for sale. Our facilities adhere to strict environmental regulations, ensuring our operations are not only efficient but also eco-friendly.

Our long-term success is rooted in the trust and satisfaction of our clients. We strive to be more than just a supplier; we aim to be a reliable partner in your success.

The selection of the right square tubing for sale is a strategic decision that impacts the longevity, safety, and efficiency of your projects. By prioritizing quality, understanding the manufacturing process, and partnering with an authoritative and trustworthy supplier, you ensure optimal performance and lasting value. Whether your project demands the robust strength of square metal tubing for sale or the lightweight efficiency of aluminum square tubing for sale, a comprehensive understanding of the product and its journey from raw material to application is key. Our expertise, experience, and commitment to transparency make us the preferred choice for all your square tubing needs.

For further insights into material science and structural applications of tubing, consider reviewing academic journals and industry standards. A notable reference for structural tubing specifications is often found within the publications of the American Institute of Steel Construction (AISC) and the American Society for Testing and Materials (ASTM). For example, the "Steel Construction Manual" by AISC frequently discusses the design and properties of structural hollow sections. Additionally, articles on cold-formed steel structures in journals like "Thin-Walled Structures" provide in-depth technical analysis.

- American Institute of Steel Construction (AISC) - https://www.aisc.org/

- ASTM International - https://www.astm.org/

- Journal of Thin-Walled Structures - (Example reference, specific article link would vary): https://www.sciencedirect.com/journal/thin-walled-structures