- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

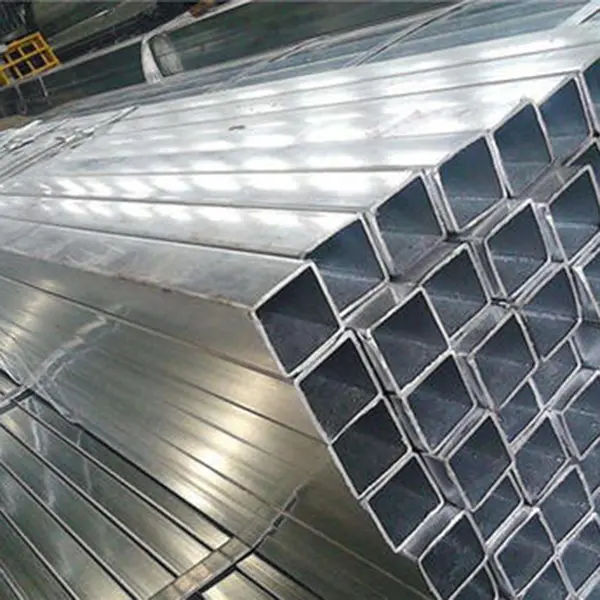

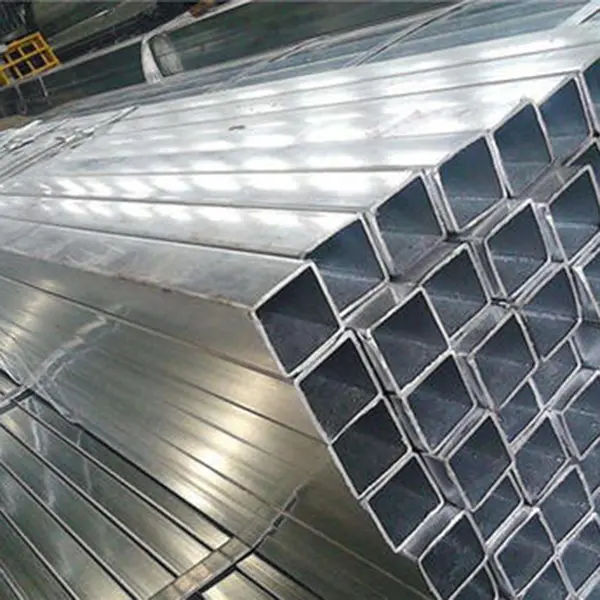

High-Quality Square Tubing for Sale – Durable Metal & Aluminum Options

Discover the latest trends, technical specifications, and competitive advantages of square tubing for sale in industrial and architectural applications. Dive into material selections, manufacturing flowcharts, real-world case studies, and data-driven comparisons to empower your purchasing decisions.

Square Tubing Industry Trends (2024): Growth, Demand, and Technology

The global square tubing for sale market is projected to reach USD 11.8 billion by 2028 (source), driven by rising demands in construction, automotive, energy, and infrastructure sectors.

Key growth segments include aluminum square tubing for sale (expected CAGR: 4.6%) and square metal tubing for sale (notably carbon and stainless steel grades).

- Growing preference for lightweight, corrosion-resistant tubing in modern engineering solutions.

- Investments in CNC precision manufacturing and post-processing.

- Customized profiles and enhanced mechanical performance becoming mainstream among OEM & EPC clients.

Square Tubing Technical Specifications & Parameter Table

| Parameter | Carbon Steel | Stainless Steel (304/316) | Aluminum (6061-T6) |

|---|---|---|---|

| Common Sizes (mm) | 20x20–400x400 | 10x10–200x200 | 12x12–150x150 |

| Wall Thickness (mm) | 1.5–20 | 1–12 | 1.2–10 |

| Yield Strength (MPa) | 235–420 | 205–520 | 160–275 |

| Density (g/cm³) | 7.85 | 8.0 | 2.70 |

| Corrosion Resistance | Low unless galvanized | Excellent | Very good (natural oxide) |

| Common Standard | ASTM A500/A513, ISO 9329 | ASTM A554, ISO 1127 | ASTM B221, EN 755 |

| Typical Applications | Structural, frames, supports | Food, pharma, outdoors | Decor, lightweight frames |

| Average Lifespan (years) | 20–40 | 30–70 | 15–35 |

2020-2024 Global Demand Trend: Square Metal Tubing for Sale

Manufacturing Process of Square Tubing for Sale

Key Node Explanations: Raw Material → Forming (roll bending or extrusion) → Auto-seam welding (ERW/TIG/MIG) → Finishing (pickling, cutting, deburring, CNC).

Material Options: Carbon steel, aluminum square tubing for sale (6061-T6/6082-T6), stainless steel (304/316L) — each optimized for durability and specific corrosion, strength, and weldability requirements.

Surface Treatments: Hot-dip galvanizing, powder coating, sandblasting, anodizing (for aluminum).

Precision Tolerances: ±0.2mm typical per ISO/EN.

Technical Indices: Square Metal Tubing for Sale Vs. Alternatives

Square Tube: Product Feature & Specification Highlights

| Feature | Description |

|---|---|

| Product Name | Square Tube |

| Product Link | View Square Tubing for Sale |

| Dimensions Range | 10x10mm up to 400x400mm; Wall thickness 1–20mm |

| Lengths | Typically 6m (customizable: 1–12m) |

| Finish | Black, galvanized, powder-coated, brushed (aluminum/stainless) |

| Compliance | ISO 9001, ASTM A500, EN 10219, ANSI B36.10 |

| MOQ | 1 ton for standard stock; 2–5 tons for custom |

| Delivery | Stock: 3-7 days; Custom: 15–30 days |

Industry Applications: Where Square Tubing for Sale Excels

- Construction & Civil Engineering: Structural beams, curtain walls, roof trusses (often require ASTM A500 Class B/C).

- Automotive & Transportation: Chassis, bumpers, roll cages, railings — lightweight yet strong solutions using aluminum square tubing.

- Oil, Gas & Petrochemical: Pipe racks, instrument supports, and skids — require certification to ISO/EN standards, exceptional corrosion resistance.

- Water Supply & Sewage: Bracing, frame supports in municipal waterworks, corrosion-resistant stainless steel tubes preferred.

- OEM Fabrication: Custom CNC-milled, drilled, finished square metal tubing for sale for production lines, workstations.

- Architectural & Decorative: Fences, frames, staircase railings, greenhouses.

- Renewable Energy: Solar panel frames, wind tower internals (aluminum/stainless applications for lower weight and maintenance).

Technological Advantages of Square Tubing for Sale

- Precision manufacturing (CNC/laser cutting): +/-0.2mm for seamless production-to-installation fit.

- High corrosion resistance (with proper finishes): Extends service life in demanding oil & gas, marine, and chemical settings.

- High load-to-weight ratio: Outperforms round tubing of comparable mass for frame rigidity.

- Versatile fabricability: Easy for cutting, drilling, bolting, and automated welding in complex assemblies.

- Certified compliance: All shipments supplied with MTC (Material Test Certificate), ultrasonic and pressure testing according to ISO/EN.

Square Tubing Manufacturer Comparison (2024)

| Manufacturer | Region | Material Options | Certifications | MOQ | Lead Time | Custom Processing |

|---|---|---|---|---|---|---|

| Szpipefitting (Square Tube) | China/EU/Global | CS, SS, Alum | ISO, ASTM, EN, CE | 1T/Spec | 7–15d | Yes (CNC, finish) |

| Vishal Steel | India/EU | SS, CS | ISO, ASTM | 2–5T | 14–30d | Yes |

| Parker Steel | USA/UK | CS, SS, Alum | ASTM, EN | None | 2–10d | Limited |

| Alro Metals | USA | Alum, CS | ISO, EN | None | 1–7d | Laser cutting |

Custom Square Tubing Solutions and Application Case Studies

Client: Shanghai Mass Transit Construction

Specs: 80x80x4mm, hot-dip galvanized steel, 9m lengths

Process: Automatic roll forming, continuous seam welding, robotic deburring. Supplied ready-to-install, each piece laser-etched with unique serial for traceability.

Results: 45% assembly labor saving, zero failures on ISO 6892-1 tensile and EN 10219 impact tests.

Client: Abu Dhabi Port Authority

Specs: 120x120x10mm, SS316, polished, 6m

Process: Custom CNC drilling, base plate welding, full MTC and salt spray ASTM B117 tested.

Results: >20-year projected life, no corrosion observed after simulated 2,500-hour salt spray exposure.

Professional FAQ: Square Tubing for Sale Industry Terminology

Quality Assurance, Delivery & Customer Support

- Inspection Protocol: 100% dimensional, surface, weld, and pressure test — comply with ISO, ASTM, and EN norms. Independent third-party inspection supported (SGS, BV, TUV).

- Packing: Industrial packaging with bundled wrapping/pallets, barcode labeling, seaworthy standards.

- Traceability: Each batch marked with heat/lot number and MTC for full traceability in project documentation.

- Delivery: Express air for samples (

- Warranty: Minimum 2-year warranty; process guarantee or full replacement for certified defects.

- After-sales/Support: Bilingual support, real-time logistics, and installation guidance available worldwide.

Conclusion: The Competitive Edge of Square Tubing for Sale

Square tubing for sale remains a cornerstone in modern industry, construction, and infrastructure. With rapid advances in CNC and coating technology, buyers can now source precision-tolerance, application-specific square metal tubing for sale directly from certified vendors worldwide. Whether aiming for structural durability, corrosion immunity, or easier fabrication, the correct material and process choices make all the difference.

Look for ISO, ASTM, and EN certification, proven real-world case studies, and manufacturer support to ensure your projects achieve long-term performance and compliance.

Steel Tube Market Size & Forecast, MarketsandMarkets, 2023

Metal Tubing Extrusion Technical Notes, eFunda

ASTM A500 / A500M–21 Standard Specification for Cold-Formed Welded...

Structural engineering applications forum, Eng-Tips

Research: Corrosion and Mechanical Performance of Steel and Aluminium Tubing, ResearchGate