- Moafrika

- Sealbania

- Seamharic

- Searabia

- Searmenia

- Se-Azerbaijani

- Sebasque

- Sebelarusia

- Benghali

- Sebosnia

- Se-Bulgaria

- Secatalan

- Sebuano

- Corsican

- Secroatia

- Czech

- Sedanishe

- Se-Dutch

- Senyesemane

- Esperanto

- Seestonia

- Sefinnishe

- Sefora

- Sefrisia

- Segalician

- Segeorgia

- Sejeremane

- Segerike

- Segujarati

- Secreole sa Haiti

- Hausa

- siwaiian

- Seheberu

- Che

- Miao

- Se-Hungary

- Seiceland

- igbo

- Seindonesia

- irish

- Setaliana

- Sejapane

- Se-Javanese

- Kannada

- kazakh

- Khmer

- Rwanda

- Sekorea

- Sekurdish

- Sekyrgyz

- Mosebetsi

- Selatine

- Selatvia

- Selithuania

- Se-Luxembourgish

- Semacedonia

- Semalagasy

- Semalay

- Semalayalam

- Semalta

- Semaori

- Marathi

- Mongolian

- Myanmar

- tsa Nepali

- Norwegian

- Norwegian

- Occitan

- Sepashto

- Sepersia

- Sepolishe

- Sepotoketsi

- Sepunjabi

- Seromania

- Serussia

- Sesamoa

- Segaeli sa Scotland

- Seserbia

- Senyesemane

- Seshona

- Sindhi

- Sesinhala

- Seslovak

- Seslovenia

- Somalia

- Sepanish

- Sesundanese

- Seswahili

- Seswedishe

- Setagalog

- Se-Tajik

- Setamil

- Setatare

- Setelugu

- Sethai

- Se-Turkey

- Turkmen

- Seukraine

- Seurdu

- Uighur

- Seuzbek

- Sevietnam

- Welsh

- Thusa

- Yiddish

- Yoruba

Lisebelisoa tsa Lipeipi ka Boenjiniere ba Marine le Offshore

Mosebetsi oa Lisebelisoa tsa Lipeipi Libakeng tsa Marine

Boenjineng ba leoatle le kantle ho naha, lisebelisoa tsa liphaephe li sebeletsa merero e latelang:

Taolo ea tataiso - ho sebelisa litsoe le ho kobeha ho tsamaisa tsamaiso ea lipeipi hantle libakeng tse koaletsoeng.

Phallo kabo - ho sebelisa li-tee, lifapano, le li-wyes ho arola kapa ho kopanya phallo ea mokelikeli.

Phetoho ea bophara - ho sebelisa li-reducers le li-swages bakeng sa boholo bo fapaneng ba liphaephe.

Khokahano ea sistimi - ka likhokahano, mekhatlo ea basebetsi, li-flanges le li-adapter.

Ho tiisa le ho itšehla thajana - ho sebelisa likatiba, li-plug le li-valve ho emisa kapa ho laola phallo.

Ho thibela khatello - e nang le lisebelisoa tse entsoeng ka likhatello tse phahameng kapa tse cheselitsoeng ho etsa bonnete ba hore ts'ebetso e sa lutle tlas'a khatello e feteletseng.

Lisebelisoa tsena li tlameha ho tsamaellana le lits'ebetso tsa lipeipi tse sebetsanang le metsi, moea, oli, mafura, mafura, lik'hemik'hale, esita le likhase tse sebelisoang lits'ebetsong tsa ho qoela le ho tima mollo.

Libaka tsa Kopo tsa Bohlokoa

Kaho ea Likepe le Likepe tsa Metsing

Likepe—ho kopanyelletsa le likepe tse tsamaisang thepa, likepe tsa litanka, likepe tse tsamaeang ka sekepe le likepe tsa sesole—li na le liphaephe tse rarahaneng tse itšetlehileng ka liphaephe tse tšoarellang nako e telele le tse baballang sebaka.

Litsamaiso tse tloaelehileng tse sebelisang li-fittings tsa pipe li kenyelletsa:

Sistimi ea ho futhumatsa metsi a leoatle (bakeng sa ho futhumatsa enjine le mochini)

Sistimi ea metsi a Ballast (e sebelisetsoa ho tsitsisa sekepe)

Litsamaiso tsa phetisetso ea mafura le oli

Litima-mollo le marang-rang a ho fafatsa

Litsamaiso tse hatelitsoeng tsa moea le tsa bilige

Methapo ea ho hloekisa metsi a nooang le litšila

Lisebelisoa tse ka har'a sistimi ena hangata li entsoe ka thepa e sa bolaeeng ke kutu joalo ka koporo-nickel, tšepe e sa hloekang ea duplex, kapa tšepe e koahetsoeng ka k'habone, ho latela ts'ebeliso. Libaka tse koaletsoeng likepeng li hloka li-fittings tse nepahetseng, tse kang li-elbows tse khutšoanyane le li-flange tse kopanetsoeng.

Libaka tsa Oli le Khase tsa Offshore

Li-platform tsa Offshore li na le litsamaiso tse ngata tse hokahaneng, ho kenyelletsa ho cheka, tlhahiso, ts'ebetso, polokeho le libaka tsa bolulo. Lisebelisoa tsa liphaephe tse sebelisoang li tlameha ho sebetsa ka botšepehi sebakeng se nang le letsoai le phahameng, mongobo o phahameng, 'me hangata se na le khatello e phahameng.

Lisebelisoa tsa bohlokoa li kenyelletsa:

Lithapo tsa taolo ea li-hydraulic bakeng sa ts'ebetso ea valve

Liphaephe tse entsoeng ka metsi le oli e tala

Litsamaiso tsa ho phatloha ha khase le moea o kenang

Mehala ea ente ea khatello e phahameng (metsi, khase kapa lik'hemik'hale)

Sistimi ea metsi a mollo bohlokoa bakeng sa polokeho le karabelo ea tshohanyetso

Lits'ebetsong tsena, li-fittings hangata li qhekelloa kapa li entsoe ka butt-welded 'me hangata li entsoe ka li-alloys tse hanang ho bola. Hangata litekanyetso tsa NORSOK le API li lateloa litsing tsena.

Liphaephe tsa Subsea le Lisebelisoa

Liphaephe tse tsamaeang ka tlas'a leoatle li tsamaisa oli, khase le lik'hemik'hale ho tloha lilibeng tse ka thōko ho leoatle ho ea libakeng tsa ho sebetsa kapa polokelo. Liphaephe tsena li behiloe fatše holim'a leoatle, hangata botebong bo boholo, e leng se etsang hore ho tšoarella le ho hanyetsa khatello ea ka ntle le ho bola e be tsa bohlokoa ka ho feletseng.

Lisebelisoa tsa lipeipi tse sebelisoang ka tlas'a leoatle li tlameha ho ba:

E cheselitsoe kapa e entsoe ka kotsi e nyane ea ho lutla

E entsoe bakeng sa matšeliso a khatello le ho hanyetsa kholo ea leoatle

E na le li-anti-corrosion coatings kapa tšireletso ea cathodic

Lisebelisoa tse khethehileng tsa subsea li sebelisoa ho:

Risers le flowlines

Li-manifolds le li-jumper spools

Li-Umbilical termination units

Likou tsa likolobe le ho hlahloba

Lisebelisoa hangata li kenyelletsa tšepe e sa hloekang ea super duplex, Inconel, kapa tšepe ea k'habone e kentsoeng ho mamella khatello ea maikutlo le ho pepesehela lik'hemik'hale.

Ho Nahana ka Lintho Tse Bonahalang

Corrosion ke eona ntho e tšoenyang haholo lits'ebetsong tsa metsing le kantle ho naha. Ka hona, khetho ea thepa bakeng sa lisebelisoa tsa liphaephe ke ea bohlokoa:

Copper-Nickel (CuNi): E tloaeleha lits'ebetsong tsa metsi a leoatle ka lebaka la ho hanyetsa ho hoholo ha kutu le ho hanyetsa biofouling.

Duplex le Super Duplex Stainless Steel: E fana ka matla a phahameng le ho hanyetsa kutu, e loketseng maemo a khatello e phahameng le a nang le chloride e ngata.

Carbon Steel e nang le Liaparo: Khetho ea moruo bakeng sa libaka tse fokolang, tse atisang ho sireletsoa ke epoxy, li-coatings tsa zinki, kapa mekhoa ea cathodic.

Titanium kapa Inconel: E sebelisoa maemong a feteletseng ka ho fetesisa moo ho hlokahala kutu, khatello le ho hanyetsa mocheso.

Maemo le Setifikeiti

Lisebelisoa tsa liphaephe bakeng sa boenjiniere ba leoatleng le lebōpong la leoatle li tlameha ho finyella litekanyetso tsa sechaba le mekhoa ea machaba, e kang:

DNV (Det Norske Veritas)

ABS (Amerika ea Lefapha la Thomello)

Ngoliso ea Lloyd

BV (Bureau Veritas)

ISO 15590, ASME B16.9, API 5L, API 6A

Traceability, litifikeiti tsa tlhahlobo ea thepa (MTCs), tlhahlobo ea khatello, le NDT (liteko tse sa senyeheng) hangata lia tlama bakeng sa lits'ebetso tse kantle ho naha.

Mathata le Litlhaloso

Ho senyeha ha metsi a letsoai: Ho pepesehela metsi a leoatle khafetsa ho lebisa ho senyeha ha tšepe ka potlako.

Meeli ea sebaka: Mehaho ea metsing hangata e hloka meralo e loketseng le e hlophisitsoeng hantle.

Ho fihlella ho boloka: Lisebelisoa li tlameha ho fumaneha 'me hangata li kenyelle likhokahano tse nang le flanged bakeng sa ho qhaqha habonolo.

Khatello le ho thothomela: Litefiso tse phahameng tsa phallo le lisebelisoa tse tsamaeang li hloka li-fittings tse sa sisinyeheng le tse thibelang mokhathala.

Mekhoa ea Bokamoso

Ka nts'etsopele e ntseng e eketseha ea lebopong la leoatle joalo ka sethala sa LNG (FLNG) se phaphametseng, masimo a oli a botebong ba metsi, le lisebelisoa tse nchafalitsoeng tsa matla (moea o tsoang lebopong le maqhubu a leoatle), tlhokahalo ea liphaephe tse sebetsang hantle haholo e ntse e hola. Lintho tse ncha li kenyelletsa:

Lisebelisoa tsa spool tse entsoeng esale pele bakeng sa ho kenya modular

Lisebelisoa tse bohlale e nang le lisensara bakeng sa ho lemoha ho lutla le ho beha leihlo khatello

Lisebelisoa tsa lipeipi tse kopantsoeng e fanang ka ho hanyetsa ho bola le ho fokotsa boima ba 'mele

Boenjinering ba leoatleng le lebopong la leoatle, lisebelisoa tsa lipeipi ke likarolo tsa bohlokoa tse netefatsang ts'ebetso e bolokehileng le e sebetsang ea marang-rang a rarahaneng a lipeipi. Ho tloha ho pholileng ka har'a likepe tsa likepe le litsamaiso tsa ballast ho ea ho lipalangoang tsa oli tse ka tlas'a leoatle le khatello ea mollo lipolaneteng tsa kantle ho naha, lisebelisoa tsena li tlameha ho sebetsa ka ts'epo tlasa maemo a feteletseng. Khetho ea thepa, moralo le litekanyetso li phetha karolo ea bohlokoa ho khethollang ts'ebetso ea bona ea nako e telele. Ha mahlale a kantle ho naha a ntse a tsoela pele le ho kenella metsing a tebileng le libakeng tse hole, karolo ea lipeipi tsa boleng bo holimo, tse sa jeng, le tse entsoeng ka nepo e tla ba tsa bohlokoa le ho feta.

- Pipe ea tšepe

- Lisebelisoa tsa Lipeipi tsa Tšepe tse Malleable

- Lisebelisoa tsa Pipe ea Carbon Steel 3000lbs, 6000lbs

- Li-Nipples tsa Moqomo oa Galvanized

- Masenke King Nipples

- Khokahano ea tšepe ea Carbon

- Lisebelisoa tsa Pipe ea Stainless Steel

- Valve ea bolo ea tšepe e se nang tšepe

- Ptfe Seal Tape

- Flange

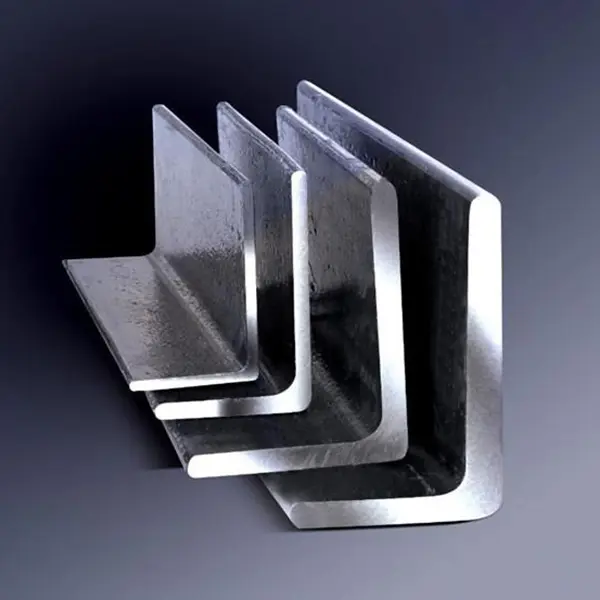

- Lisebelisoa tsa tšepe

- Kopanelo ea Katoloso ea Rabara

- Lehae

- Lihlahisoa

- Pipe ea tšepe

- Lisebelisoa tsa Lipeipi tsa Tšepe tse Malleable

- Lisebelisoa tsa Pipe ea Carbon Steel 3000lbs, 6000lbs

- Li-Nipples tsa Moqomo oa Galvanized

- Masenke King Nipples

- Khokahano ea tšepe ea Carbon

- Lisebelisoa tsa Pipe ea Stainless Steel

- Valve ea bolo ea tšepe e se nang tšepe

- Ptfe Seal Tape

- Flange

- Litšepe Bar

- Kopanelo ea Katoloso ea Rabara

- Kopo

- Mabapi le rona

- FAQs

- Litaba

- Iteanye le rona

- lihlahisoa tse hlahisitsoeng

Tlhokomediso: Senotlolo sa sehlopha se sa hlalosoang "array_images_sha2r_all" ho /home/www/wwwroot/HTML/www.exportstart.com/wp-content/themes/1419/footer.php mocheng 117

Tlhokomediso: foreach() khang e tlameha ho ba ea mofuta oa array|object, null given in /home/www/wwwroot/HTML/www.exportstart.com/wp-content/themes/1419/footer.php mocheng 117